WMS Systems: Streamlining US Warehouse Operations

Riten Debnath

26 Aug, 2025

In today’s fast-moving US market, effective warehouse management can make or break a company’s ability to meet customer expectations. Warehouses are no longer just storage spaces; they are high-tech hubs that require precise coordination, real-time data, and efficient workflows. A Warehouse Management System, or WMS, is the technology that ties it all together by improving accuracy, reducing costs, and speeding up order fulfillment.

I’m Riten, founder of Fueler, a platform that helps freelancers and professionals get hired through their work samples. Just as in hiring, where demonstrating real skills through a portfolio builds trust and credibility, implementing a WMS successfully means showcasing how warehouse operations work smoothly with smart technology. This article guides you through the essential elements of WMS systems and why they are game-changers for streamlining warehouse operations in the US.

What is a Warehouse Management System (WMS)?

A WMS is software designed to manage and optimize warehouse activities like inventory tracking, picking and packing, shipping, and receiving. Unlike simple inventory software, a WMS gives you real-time control and detailed visibility at every stage of the warehouse workflow, leading to better decision-making.

- Tracks inventory locations in real time

- Automates picking, packing, and shipping workflows

- Manages labor and equipment efficiently

- Integrates with shipping carriers and ERP systems

Why it matters: WMS helps warehouses handle larger volumes with fewer errors, reducing delays and improving customer satisfaction crucial factors in the highly competitive US supply chain ecosystem.

Key Benefits of Using a WMS in US Warehouses

1. Real-Time Inventory Accuracy

Maintaining accurate inventory counts is one of a warehouse’s biggest challenges. WMS solutions use barcode scanning, RFID, and real-time data updates to ensure stock levels are exact, helping avoid stockouts and overstock situations.

- Automated inventory updates as goods are moved or scanned

- Alerts for low stock and replenishment needs

- Detailed tracking of batch numbers and expiry dates

- Improved order accuracy with fewer manual errors

Why it matters: Precise inventory data means better demand forecasting, minimized waste, and the ability to fulfill orders quickly, keeping customers loyal and operations running smoothly.

2. Increased Labor Productivity

Efficient labor management is vital to managing costs and meeting deadlines. WMS optimizes who does what task, reducing idle time and ensuring the fastest possible workflows.

- Task prioritization based on order urgency and location

- Optimized walking routes to minimize worker travel time

- Real-time labor performance tracking and reporting

- Automated shift planning and scheduling

Why it matters: When every minute counts, maximizing labor productivity increases throughput without increasing costs — a necessary edge in the competitive US warehousing sector.

3. Enhanced Order Fulfillment Speed

Today’s customers expect fast, accurate deliveries. A WMS accelerates picking, packing, and shipping by providing workers with clear instructions and automating parts of the process.

- Support for pick-by-light, voice picking, and paperless workflows

- Real-time order status tracking for faster processing

- Integration with shipping systems for automated label printing

- Efficient batch and wave picking capabilities

Why it matters: Faster fulfillment translates into happier customers, fewer returns, and better reputation in the crowded US ecommerce market.

4. Space Utilization and Warehouse Layout Optimization

Goods stored inefficiently waste valuable space and slow down operations. Modern WMS platforms analyze storage patterns and optimize warehouse layouts to save space and improve flow.

- Mapping of storage locations by size, weight, and product type

- Recommendations for slotting high-demand items closer to packing areas

- Simulation tools to plan changes before implementation

- Dynamic reallocation of space based on seasonality and trends

Why it matters: Smart space management lowers costs and boosts capacity, allowing warehouses to handle growth without expensive expansions.

5. Integration with Other Systems

A WMS doesn’t operate in isolation. It must work smoothly with ERP, transportation management, and other enterprise systems to ensure end-to-end visibility and control.

- Pre-built APIs for common ERP and shipping software

- Real-time data syncing to eliminate double entry

- Centralized dashboards for monitoring multiple systems

- Support for EDI and other communication protocols

Why it matters: Integrated systems reduce errors and manual work, giving warehouse managers a unified platform to run their operations efficiently.

Fueler — The Hiring Connection

Just as Fueler helps companies connect with qualified professionals by evaluating their real skills through assignments, a WMS serves as the operational “portfolio” for your warehouse — showing real-time, verified workflows that prove your efficiency. Hiring the right talent to operate and maintain your WMS is crucial. Using platforms like Fueler, managers can find skilled warehouse professionals who demonstrate their capabilities upfront, much like a solid WMS proves operational excellence.

Final Thoughts

The US warehouse industry is undergoing a technological revolution with Warehouse Management Systems at its core. Investing in a robust WMS is no longer optional but essential for companies looking to reduce errors, speed fulfillment, and scale sustainably. By embracing real-time data, automation, and integration, warehouses can become lean, agile hubs capable of meeting increasing consumer demands.

Frequently Asked Questions

1. What are the main features to look for in a WMS system?

Look for real-time inventory tracking, labor management, order fulfillment automation, space optimization, and easy integration capabilities.

2. How much does a Warehouse Management System cost in the US?

Costs vary widely based on size and features, typically ranging from $10,000 to $100,000+ annually, including software licenses and implementation.

3. Can a WMS improve warehouse safety?

Yes, by optimizing workflows, reducing manual handling, and providing clear task instructions, a WMS helps minimize accidents and ergonomic risks.

4. How long does it take to implement a WMS?

Implementation times vary from a few weeks for small warehouses to several months for complex operations.

5. Can WMS systems integrate with existing warehouse hardware like barcode scanners?

Yes, most modern WMS platforms support integration with standard warehouse equipment including barcode scanners, RFID readers, and mobile devices.

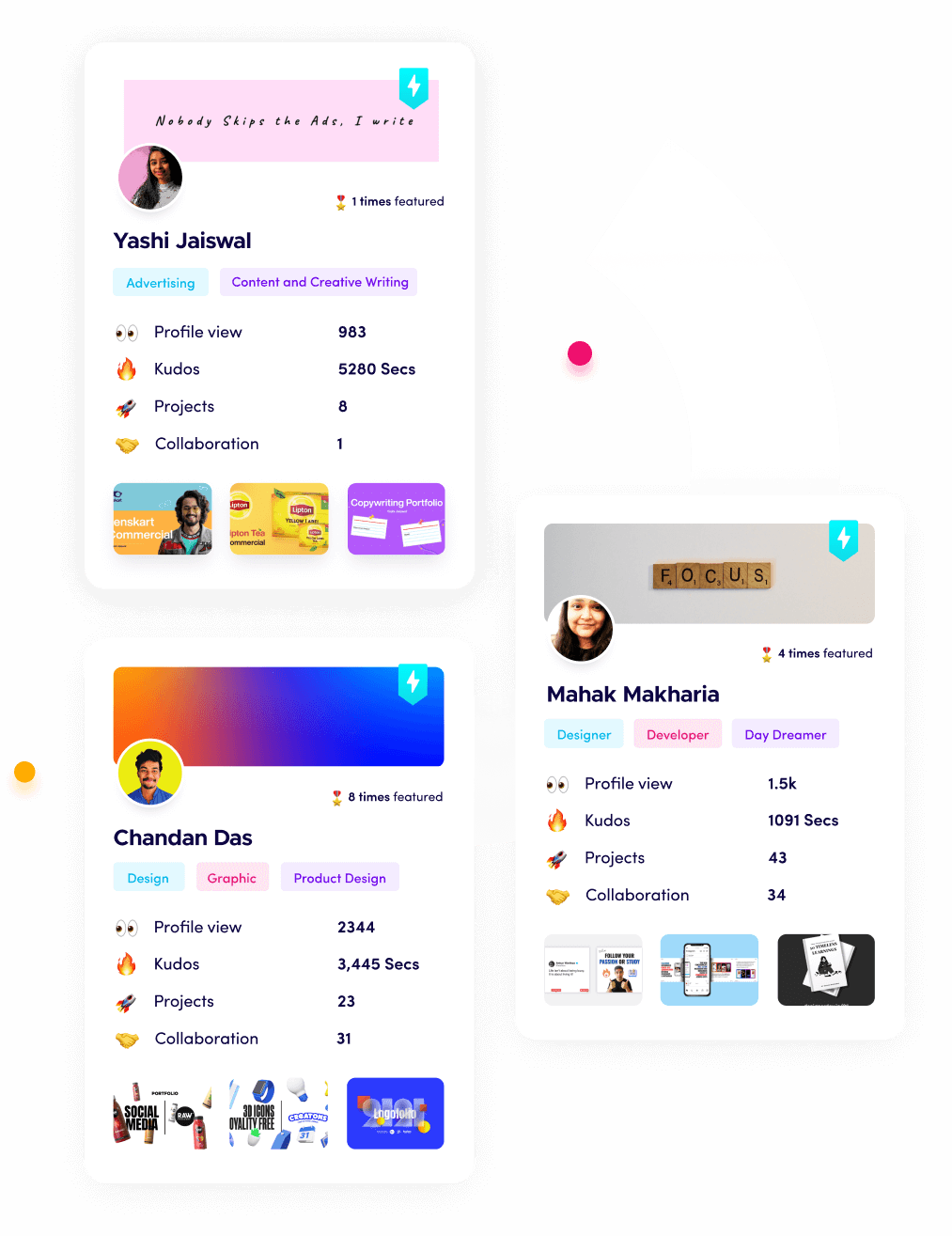

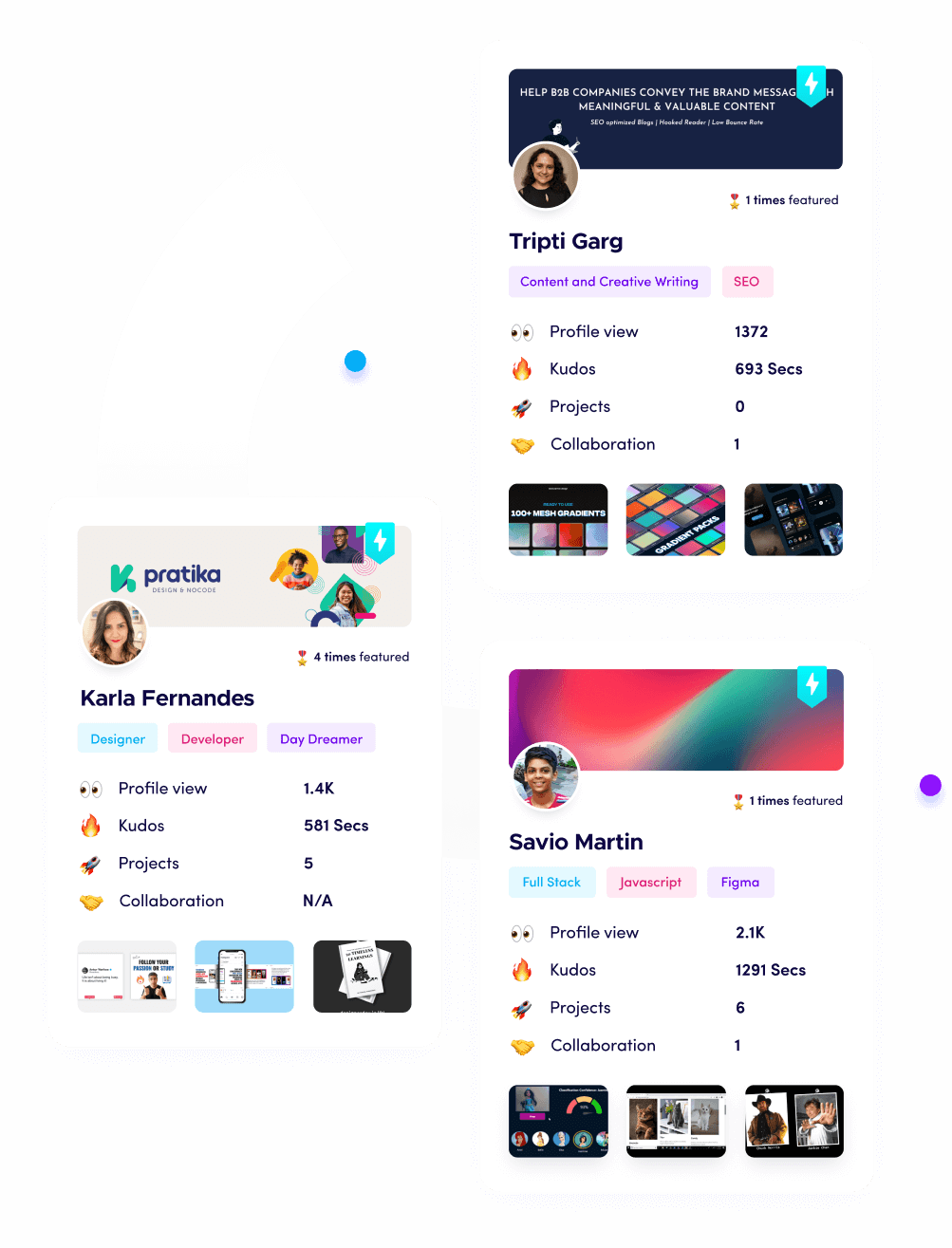

What is Fueler Portfolio?

Fueler is a career portfolio platform that helps companies find the best talents for their organization based on their proof of work.

You can create your portfolio on Fueler, thousands of freelancers around the world use Fueler to create their professional-looking portfolios and become financially independent. Discover inspiration for your portfolio

Sign up for free on Fueler or get in touch to learn more.