8 Ways AI Can Improve Supply Chain Efficiency in 2026

Riten Debnath

11 Oct, 2025

Supply chains are the backbone of every business that delivers goods, yet they remain complex and vulnerable to disruptions. In 2026, companies are turning to Artificial Intelligence (AI) to modernize their supply chains and make them faster, smarter, and more resilient. AI-powered systems analyze vast amounts of data, predict risks before they happen, and automate critical decisions transforming how goods move from raw materials to customer doorsteps.

I’m Riten, founder of Fueler, a platform that helps freelancers and professionals get hired through their work samples. In this article, I’ll show you eight ways AI is improving supply chain efficiency in 2026. Just like businesses leverage AI to optimize operations, professionals must also showcase their skills with clear proof. A strong portfolio can demonstrate your ability to solve complex problems and stand out to employers.

What Is AI in Supply Chain Management?

At its core, AI in supply chain management means using machine learning, data analytics, and automation to improve visibility, speed, and decision-making. Instead of reacting to problems after they happen, AI systems anticipate challenges and optimize every step from sourcing to delivery.

AI helps businesses reduce costs, improve delivery times, and increase customer satisfaction by providing data-driven insights and automating routine processes.

Core AI Capabilities in Supply Chains

- Predictive analytics that forecast demand and identify supply risks early

- Automated inventory management to optimize stock levels and reduce wastage

- Intelligent route planning for logistics and delivery efficiency

- Real-time monitoring powered by IoT devices and AI analysis

Why it matters: Supply chains are increasingly global and complex. AI brings the speed and intelligence needed to manage this complexity proactively, rather than relying on guesswork.

1. Demand Forecasting with AI

Traditional demand forecasting often struggles with unforeseen market changes or seasonal spikes. AI overcomes this by analyzing historical sales data, market trends, weather patterns, social media sentiment, and economic indicators to create highly accurate demand forecasts.

How AI Improves Forecasting

- Incorporates multiple external factors to improve predictions beyond historical sales data

- Continuously updates forecasts based on real-time data streams and new information

- Detects emerging buying patterns and shifting consumer preferences early

Why it matters: Accurate demand forecasting prevents overstocking and stockouts, both of which waste money and reduce customer satisfaction. AI-powered forecasting helps balance supply and demand precisely.

2. Inventory Optimization

Inventory holding costs can be a massive financial burden if not well managed. AI helps by optimizing inventory levels across warehouses and stores based on demand forecasts, lead times, and reorder points.

Inventory Optimization Features

- AI algorithms that recommend optimal reorder quantities and timings

- Predictive alerts for stock shortages or excess inventory

- Automated replenishment workflows with suppliers

Why it matters: Optimized inventory reduces storage costs and capital lockup while ensuring products are always available when customers need them. Efficient inventory management enhances supply chain agility.

3. Supplier Risk Management

Supply chain disruptions frequently arise due to supplier failures, geopolitical issues, or natural disasters. AI systems monitor data feeds such as news, weather, political events, and supplier performance metrics to assess risk continuously.

Supplier Risk Capabilities

- Early detection of supplier reliability issues or disruptions

- Automated risk scoring of suppliers based on multiple criteria

- Recommendations for alternative suppliers or contingency plans

Why it matters: Proactive risk management reduces costly delays and helps companies maintain continuity even during unexpected disruptions.

4. Smart Logistics and Route Planning

Transportation is a major cost driver in supply chains. AI-powered logistics platforms plan optimal routes based on traffic conditions, weather, fuel costs, and delivery windows. This ensures faster deliveries and lower expenses.

Smart Logistics Features

- Dynamic route optimization that adjusts delivery paths in real time

- Load optimization to maximize truck capacity and reduce trips

- Predictive maintenance of vehicles using IoT sensors data

Why it matters: Efficient route planning improves delivery speed, reduces fuel consumption, and lowers carbon footprints, contributing to both cost savings and sustainability goals.

5. Automated Warehousing and Robotics

AI-driven automation extends inside warehouses where robots and automated systems manage picking, packing, and sorting. AI controls robotic movements to maximize accuracy and speed.

Warehouse Automation Tools

- Automated guided vehicles (AGVs) that transport pallets autonomously

- AI-powered sorting systems that identify products rapidly

- Robotics integrated with inventory management systems for real-time updates

Why it matters: Automated warehousing reduces labor costs, increases throughput, and minimizes errors, allowing supply chains to meet growing e-commerce demands.

6. Real-Time Supply Chain Visibility

End-to-end visibility remains a challenge in global supply chains. AI, combined with IoT sensors and blockchain, provides real-time tracking of goods at every stage.

Visibility Benefits

- Monitor shipment conditions such as temperature, humidity, and location

- Detect delays immediately and reroute or reschedule proactively

- Transparency for partners and customers through shared data platforms

Why it matters: Real-time supply chain visibility enables faster issue resolution, improves trust among stakeholders, and enhances customer experience.

7. Sustainable Supply Chain Practices

AI helps companies meet sustainability goals by optimizing routes to reduce emissions, managing waste through better inventory control, and selecting eco-friendly suppliers.

AI-Driven Sustainability

- Carbon footprint tracking integrated into supply chain decisions

- Waste reduction through precise demand matching and inventory planning

- Supplier evaluation based on environmental impact scores

Why it matters: Sustainability is becoming a key competitive advantage. AI enables businesses to reduce their environmental impact while cutting costs.

8. Enhanced Decision-Making with AI Insights

Finally, AI-powered supply chain platforms offer detailed analytics and scenario planning tools. Integrating tools like Suplari's spend analysis software can provide finance and procurement teams with visibility into historical and real-time spend, helping managers make smarter sourcing, budgeting, and supplier decisions. Organizations seeking comprehensive procurement solutions can partner with specialized procurement providers that offer end-to-end platforms combining AI-powered analytics, automated purchase requisitions, supplier management, contract tracking, and approval workflows to optimize spending and streamline purchasing processes across the enterprise. Managers can simulate disruptions, analyze “what-if” situations, and make smarter choices based on data-driven forecasts.

Decision Support Tools

- Interactive dashboards with customized KPIs and alerts

- AI-generated recommendations for sourcing, pricing, and distribution

- Predictive risk models that highlight potential bottlenecks

Why it matters: In a fast-changing market, agile and informed decision-making improves resilience and competitiveness significantly.

Fueler: Showcasing Your Supply Chain Expertise

Just as AI is transforming supply chains, today’s professionals must show clear evidence of their skills and knowledge to stand out. Whether you’re involved in data analytics, logistics, procurement, or AI development, being able to demonstrate real projects, models, or process improvements is crucial.

Fueler offers a simple way to build live, dynamic portfolios that display your work samples. By presenting your expertise through completed assignments, dashboards, or case studies, you make it easier for recruiters and clients to trust your capabilities. Your portfolio becomes your strongest asset in a competitive market.

Final Thoughts

AI is revolutionizing supply chains in 2026 by automating complex tasks, predicting risks, and improving decision-making processes. This transformation not only reduces costs but also enhances reliability and customer satisfaction. Companies adopting AI-powered supply chain solutions are better prepared to navigate disruptions and seize new opportunities. However, the human factor of skilled professionals capable of understanding and leveraging AI is vital for realizing these benefits in real life.

Frequently Asked Questions

1. How does AI improve supply chain forecasting accuracy?

By analyzing multiple external and internal data sources in real time, AI creates demand forecasts that adapt quickly to market shifts and avoid stock imbalances.

2. What are the best AI tools for supply chain management in 2026?

Top platforms include IBM Sterling Supply Chain, Llamasoft, Kinaxis RapidResponse, and Oracle SCM Cloud, each offering AI-powered forecasting, risk management, and automation.

3. Can AI help make supply chains more sustainable?

Yes, AI optimizes routing, inventory, and supplier choices to reduce carbon footprints, waste, and environmental impact.

4. Is real-time supply chain visibility possible with AI?

Absolutely. IoT sensors combined with AI enable real-time monitoring of shipments, warehouse conditions, and logistics status.

5. How can professionals showcase their supply chain skills effectively?

Building a portfolio with tangible work samples, case studies, and data projects on platforms like Fueler provides proof of your expertise and attracts recruiters.

What is Fueler Portfolio?

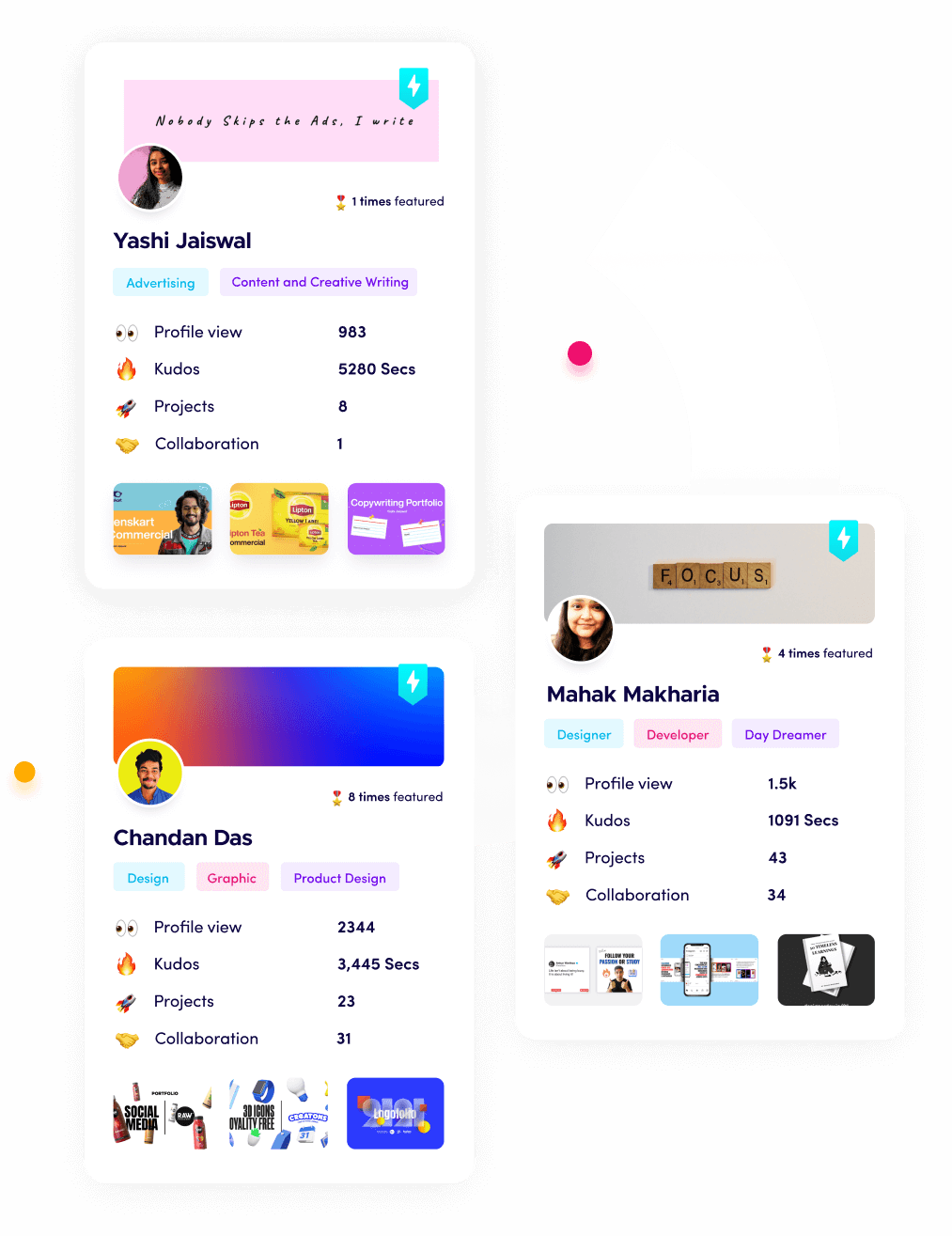

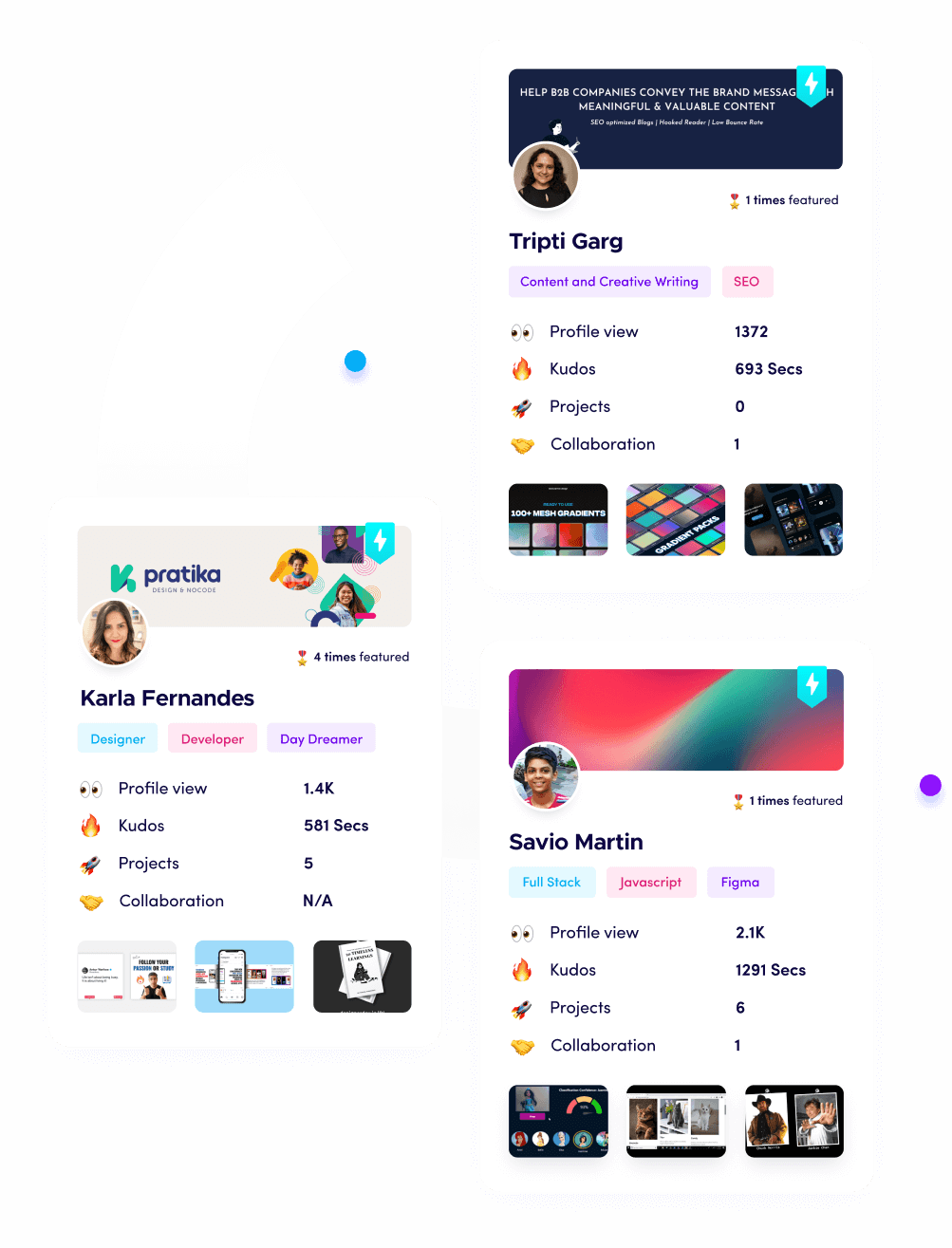

Fueler is a career portfolio platform that helps companies find the best talent for their organization based on their proof of work. You can create your portfolio on Fueler, thousands of freelancers around the world use Fueler to create their professional-looking portfolios and become financially independent. Discover inspiration for your portfolio

Sign up for free on Fueler or get in touch to learn more.