Top 15 Tech Solutions Used in US Manufacturing in 2026

Riten Debnath

19 Jan, 2026

The American manufacturing landscape is changing faster than ever before. If you walk into a modern factory today, you might see more tablets and robots than traditional heavy machinery. Companies across the United States are racing to adopt smart technologies to stay competitive, reduce waste, and bring production back home. Staying ahead in this industry means understanding the digital tools that are redefining how we build everything from electric cars to medical devices.

I’m Riten, founder of Fueler, a skills-first portfolio platform that connects talented individuals with companies through assignments, portfolios, and projects, not just resumes/CVs. Think Dribbble/Behance for work samples + AngelList for hiring infrastructure.

1. PTC ThingWorx

PTC ThingWorx is a leading Industrial Internet of Things (IIoT) platform designed to connect disparate systems and provide a unified view of factory operations. It excels in removing data silos by connecting machines, sensors, and enterprise systems into a single dashboard. This allows manufacturers to monitor equipment health and production metrics in real-time, significantly reducing the risk of unexpected mechanical failures. By utilizing advanced analytics, it transforms raw data into actionable insights that help floor managers make informed decisions quickly.

- Asset Monitoring: This feature provides a real-time digital representation of physical equipment to track performance and health across multiple factory locations simultaneously.

- Predictive Analytics: The platform uses machine learning models to identify patterns in equipment behavior, alerting staff to potential issues before a breakdown occurs.

- Rapid Application Development: Users can build custom industrial applications with a drag and drop interface, reducing the need for deep coding knowledge to create shop floor tools.

- Enterprise Integration: It seamlessly connects with existing ERP and PLM systems, ensuring that factory floor data is reflected in high-level business planning and financial reports.

- Operator Instructions: ThingWorx can deliver digital, interactive work instructions to technicians on the floor, improving accuracy and speed during complex assembly processes.

Pricing:

- Standard Enterprise licenses typically start around $15,000 per year, though specialized online cloud service tiers can be quoted as low as $200 per month for basic connectivity.

Why it matters:

This tool is the backbone of "Industry 4.0" in the US because it gives managers total visibility. When every machine is connected, manufacturers can eliminate waste and respond to supply chain shifts with incredible speed.

2. Microsoft Dynamics 365 Supply Chain Management

Microsoft Dynamics 365 is a comprehensive Cloud ERP solution that handles everything from the initial order to the final shipment. It is particularly popular in the US for its ability to integrate with the familiar Microsoft Office ecosystem, making it easy for staff to adopt. The platform uses artificial intelligence to optimize inventory levels, ensuring that factories never run out of raw materials while also avoiding the costs of overstocking. It provides a robust framework for managing complex global supply chains with high transparency.

- AI-Driven Demand Forecasting: The system analyzes historical sales data and market trends to predict future product demand, helping planners schedule production runs more accurately.

- Warehouse Management: This feature automates material handling and stock movements using mobile devices, ensuring that every pallet is tracked from the moment it arrives.

- Production Floor Execution: It provides a dedicated interface for shop floor workers to report progress, track time, and manage material consumption in real-time.

- Master Planning: The tool calculates the most efficient way to use resources, including labor and machinery, to meet delivery deadlines without increasing operational costs.

- Vendor Collaboration: Manufacturers can share real-time data with their suppliers, allowing for better coordination on shipping dates and quality control standards.

Pricing:

- Full user licenses start at $180 per user per month, with "Team Member" access for light users priced at approximately $8 per month.

Why it matters:

For American manufacturers, managing a complex supply chain is the biggest challenge of the modern era. Dynamics 365 provides the organizational structure needed to keep production lines moving even when global logistics are unpredictable.

3. Autodesk Fusion for Manufacturing

Autodesk Fusion is a cloud-based CAD, CAM, and CAE platform that bridges the gap between design and actual production. It allows engineers to create complex 3D models and then immediately generate the toolpaths needed for CNC machines to cut the parts. Because it lives in the cloud, teams across different time zones can collaborate on the same design file without version control issues. This integration speeds up the transition from a digital concept to a physical product, which is critical for rapid prototyping.

- Integrated CAD and CAM: The software eliminates the need to switch between different programs for design and machining, ensuring that any design change is automatically reflected in the manufacturing instructions.

- Generative Design: Engineers can input specific constraints like weight or material type, and the AI will generate hundreds of high-performance design options that a human might not have imagined.

- Additive Manufacturing Tools: It includes specialized features for preparing 3D prints, including support structure generation and orientation optimization for metal and plastic printers.

- Cloud Collaboration: Multiple stakeholders can leave comments, view versions, and approve designs from any device, including tablets and smartphones, directly on the shop floor.

- Simulation and Testing: Before a single piece of metal is cut, the software can simulate stress, heat, and vibration to ensure the part will not fail under real-world conditions.

Pricing:

- The manufacturing-specific extension package is priced at approximately $1,350 per year per user, while basic versions start around $680 per year.

Why it matters:

Speed to market is a major competitive advantage for US companies. Fusion for Manufacturing allows teams to design, test, and build in one environment, cutting weeks off the traditional product development cycle.

4. Tulip Interfaces

Tulip is a "Frontline Operations Platform" that allows manufacturers to build custom apps for their workers without needing a team of software engineers. These apps can be used for quality inspections, tracking production steps, or providing interactive training videos. By putting digital tools in the hands of the people actually building the products, Tulip helps eliminate paper-based processes. It is widely used in the US to help bridge the skills gap by making complex tasks easier to follow for new hires.

- No-Code App Builder: Using a simple visual interface, shop floor managers can create custom applications that guide workers through specific assembly or maintenance procedures.

- Edge Connectivity: The platform can connect directly to sensors, cameras, and smart tools on the floor to collect data automatically as work is being performed.

- Digital Work Instructions: It replaces dusty paper manuals with interactive screens that can include photos, videos, and real-time feedback loops to ensure zero-defect manufacturing.

- Quality Management: Workers can perform digital inspections and log defects instantly, allowing quality control teams to spot trends and fix issues before they become widespread.

- Real-Time Visibility: Dashboards show exactly what is happening at every station, giving management a bird's-eye view of productivity and bottlenecks throughout the shift.

Pricing:

- The Professional tier starts at $2,400 per interface per year, while the Essentials tier is available for $1,200 per interface per year with a minimum requirement.

Why it matters:

American factories often struggle with high turnover or a lack of specialized labor. Tulip empowers the existing workforce by making their jobs more intuitive and removing the friction of manual data entry.

5. Mastercam 2026

Mastercam is the most widely used Computer-Aided Manufacturing (CAM) software in the world, specifically designed to program CNC machinery. The 2026 version introduces advanced AI-enabled features that help programmers create more efficient cutting paths, which extends tool life and reduces cycle times. It supports everything from simple 2-axis milling to complex 5-axis machining used in the aerospace and defense industries. Its deep community support and wide adoption make it the industry standard for US machine shops.

- Dynamic Motion Technology: This feature uses sophisticated algorithms to keep the cutting tool at a constant load, allowing for faster cuts while significantly reducing tool wear and tear.

- Multiaxis Machining: It provides complete control over the tool axis, allowing for the creation of complex shapes and surfaces that are common in modern medical and aerospace parts.

- AI-Enabled Programming: The 2026 update includes intelligent suggestions for toolpaths based on the geometry of the part, helping junior programmers work like seasoned experts.

- Solid Model Importing: Mastercam can open files from almost any CAD software, ensuring that the transition from a designer's vision to a machinist's reality is seamless and error-free.

- Post-Processor Support: It features a massive library of machine-specific instructions, ensuring that the code generated will run perfectly on specific hardware from Haas, Fanuc, or DMG Mori.

Pricing:

- Pricing is typically quote-based through local resellers, but annual maintenance and subscription fees for professional tiers generally range from $3,000 to $5,000.

Why it matters:

Precision is everything in high-tech manufacturing. Mastercam ensures that US machine shops can produce the highest quality parts with the least amount of wasted material and time.

6. Katana Manufacturing ERP

Katana is a modern, user-friendly ERP designed specifically for smaller and medium-sized manufacturers who need to manage inventory and production in one place. It is highly popular among US "maker" businesses and growing brands because it integrates directly with e-commerce platforms like Shopify. The software provides a visual "Auto-Booking" system that shows you exactly which raw materials are available for which orders. This prevents the common mistake of starting a production run only to realize a key component is missing.

- Live Inventory Management: The software updates stock levels in real-time as orders are placed and materials are used on the shop floor, providing an accurate view of what is on hand.

- Visual Production Planning: A drag and drop calendar allows managers to re-prioritize jobs easily, and the system automatically updates the material requirements based on the new schedule.

- Shop Floor App: Operators can use their own tablets or phones to see their tasks for the day, mark jobs as started, and record the exact amount of time spent on each task.

- Contract Manufacturing Support: It allows companies that outsource their production to track inventory levels at third-party facilities, ensuring they never run out of stock.

- E-commerce Integration: It bridges the gap between the online storefront and the factory, automatically turning new sales into production orders without manual data entry.

Pricing:

- The Essential plan starts at $179 per month, while the Professional tier for larger operations is priced at approximately $599 per month.

Why it matters:

Small manufacturers are the lifeblood of the US economy. Katana gives these growing companies the same level of professional organization that giant corporations have, but at a fraction of the cost.

7. Odoo Manufacturing

Odoo is a unique, open-source ERP that uses a modular approach, meaning companies only pay for the specific tools they need. The manufacturing module is highly advanced, covering everything from Bill of Materials (BoM) management to Maintenance and Quality modules. Because it is highly customizable, it is used by a wide variety of US industries, from food and beverage to electronics. The platform's clean interface makes it easy for teams to manage complex manufacturing workflows without feeling overwhelmed by data.

- Flexible Bill of Materials: It supports multi-level BoMs and versioning, allowing engineers to track changes and manage "kits" or sub-assemblies with high precision.

- Maintenance Management: The system automatically schedules preventive maintenance based on machine usage or time intervals, helping to prevent costly equipment breakdowns.

- Integrated Quality Control: Manufacturers can set up specific quality checks at different stages of production, requiring workers to pass or fail a part before moving to the next step.

- Real-Time Work Centers: Each station on the floor can be tracked as a "Work Center," showing its capacity, efficiency, and current workload to prevent production bottlenecks.

- PLM Integration: It includes Product Lifecycle Management features that allow engineering teams to manage documents, ECOs (Engineering Change Orders), and design versions.

Pricing:

- Odoo offers a "One App Free" plan, but the Standard Cloud version for multiple apps is approximately $49 per user per month when billed annually.

Why it matters:

Odoo’s modularity allows US companies to start small and add more complex features as they grow. This "pay-as-you-go" model is perfect for startups that need to stay lean while scaling up production.

8. Stratasys GrabCAD Print

Stratasys is a giant in the 3D printing world, and their GrabCAD Print software is what makes industrial 3D printing accessible. It simplifies the process of preparing a digital file for printing on professional FDM and PolyJet machines. Instead of needing to be an expert in "slicing" software, designers can simply import their CAD files and let the software handle the technical details. This tool is essential for US aerospace and automotive companies that rely on 3D printing for rapid tooling and end-use parts.

- Native CAD File Support: Users can import files directly from programs like SOLIDWORKS or Inventor without having to convert them to STL files, preserving the original design intent.

- Remote Monitoring: Managers can check the status of their entire fleet of 3D printers from a single dashboard, even if the printers are located in different buildings.

- Advanced Material Scheduling: The software predicts how much material a print will use and how long it will take, allowing for better planning of the production schedule.

- Automatic Tray Packing: It uses intelligent algorithms to fit as many parts as possible onto a single print tray, reducing the number of print cycles needed and saving energy.

- Detailed Reporting: It provides analytics on printer usage, material consumption, and success rates, helping companies justify the cost of their additive manufacturing investments.

Pricing:

- The basic version is often included with Stratasys hardware, but Enterprise versions for fleet management are quoted based on the number of connected machines.

Why it matters:

Industrial 3D printing can be complicated. GrabCAD Print makes it "click-and-print," allowing US engineers to focus on designing better products rather than fiddling with machine settings.

9. MaintainX

MaintainX is a mobile-first maintenance and procedure management platform that helps factory teams stay on top of their equipment. It is designed to be as easy to use as a messaging app, allowing technicians to take photos of broken parts and create work orders in seconds. In many US factories, it has replaced the old system of whiteboards and verbal requests. By digitizing maintenance, companies can ensure that every machine is serviced on time, which is critical for safety and uptime.

- Mobile Work Orders: Technicians can receive, update, and complete work orders directly on their smartphones, attaching photos and voice notes to provide context.

- QR Code Scanning: Every machine can have a unique QR code; when scanned, it brings up the machine's entire history, manuals, and current maintenance tasks.

- Preventive Maintenance Scheduling: The system sends automated alerts for routine tasks like oil changes or filter replacements, ensuring nothing is ever forgotten.

- Inventory Tracking for Parts: It tracks the usage of spare parts, automatically alerting the procurement team when stock levels for critical items like belts or bearings get low.

- Reporting and Compliance: It generates detailed logs that prove maintenance was performed, which is vital for passing safety audits and maintaining industry certifications.

Pricing:

- The Essential plan is $20 per user per month, while the Premium plan with advanced features is $65 per user per month. A basic free version is also available.

Why it matters:

Equipment is the biggest investment for any manufacturer. MaintainX protects that investment by ensuring that maintenance is proactive rather than reactive, keeping US factories running smoothly.

10. Rockwell Automation FactoryTalk

FactoryTalk by Rockwell Automation is a massive suite of software tools used to monitor and control large-scale industrial operations. It is the gold standard for Human-Machine Interface (HMI) and Supervisory Control and Data Acquisition (SCADA) in the United States. This software allows operators to see a visual map of the entire factory floor, showing the status of every motor, valve, and conveyor belt. It is essential for industries like food processing and chemical manufacturing where precise control is a matter of safety.

- Visual HMI Design: It allows engineers to create intuitive touch-screen interfaces for machine operators, making it easier to control complex processes without errors.

- Data Logging and Historian: The software records every single event and data point over time, allowing engineers to "rewind" and analyze what happened during a production glitch.

- Alarm Management: It features a sophisticated alert system that prioritizes the most critical issues, ensuring that operators aren't overwhelmed by minor notifications during a crisis.

- Energy Monitoring: Specialized modules track the power consumption of different machines, helping companies identify ways to reduce their carbon footprint and utility bills.

- Distributed Architecture: The system can scale from a single machine to a global network of factories, providing a consistent interface across the entire organization.

Pricing:

- Standard software licenses for HMI components typically start around $1,800 per station, with larger enterprise SCADA systems requiring custom quotes based on the number of "tags" monitored.

Why it matters:

Large-scale manufacturing requires extreme reliability. FactoryTalk provides the heavy-duty control systems that allow American industry to operate at a massive scale with minimal risk of human error.

11. UpKeep CMMS

UpKeep is another powerful Maintenance Management System, but it places a heavy emphasis on asset management and cost tracking. It helps US manufacturers understand the "Total Cost of Ownership" for their machines by tracking every dollar spent on repairs and parts. The software is known for its excellent user interface, which makes it popular among teams that are transitioning from paper to digital for the first time. It is a great choice for facilities that need to manage both production equipment and the building itself.

- Asset Lifecycle Tracking: It keeps a digital record of every machine from the day it is purchased until it is retired, including every repair and inspection ever performed.

- Purchase Order Management: Users can create and send purchase orders for spare parts directly within the app, streamlining the relationship between maintenance and finance.

- Meter-Based Maintenance: Instead of just scheduling by date, it can trigger maintenance based on machine hours or cycles, ensuring service happens exactly when needed.

- Customizable Dashboards: Managers can create views that show key metrics like "Mean Time to Repair" (MTTR) to see how efficiently their maintenance team is working.

- Safety Checklists: It allows for the creation of mandatory safety steps that must be checked off before a technician can start or finish a repair job.

Pricing:

- The Starter plan is $40 per technician per month, while the Business Plus plan is priced at $120 per technician per month for larger organizations.

Why it matters:

Maintenance isn't just a cost; it's a way to improve profitability. UpKeep gives US managers the data they need to decide when it's cheaper to replace an old machine than to keep repairing it.

12. Fishbowl Inventory

Fishbowl is the number one requested inventory management solution for QuickBooks users in the manufacturing sector. It bridges the gap between basic accounting software and a full-scale ERP system. For many US small businesses, Fishbowl provides the "missing link" for tracking raw materials and work-in-progress (WIP). It is particularly strong in the food, medical, and electronics industries where tracking "lot numbers" and expiration dates is a legal requirement.

- Advanced Lot Tracking: It tracks every batch of raw material from the supplier to the final customer, making it easy to perform a surgical recall if a quality issue is found.

- Work Order Management: Users can create complex instructions for assembly, including "yield" tracking to see how much material is wasted during the process.

- Multi-Location Tracking: If a company has multiple warehouses or retail stores, Fishbowl provides a single view of where every single item is located at any given moment.

- Barcode Integration: It works seamlessly with mobile barcode scanners to speed up the process of receiving shipments and picking parts for production.

- Seamless QuickBooks Sync: It ensures that every inventory movement is reflected in the company's financial records without the need for manual data entry or reconciliation.

Pricing:

- The Fishbowl Essentials cloud plan starts at $199 per month for two users, while the specialized Scale plan for manufacturers starts at $699 per month for ten users.

Why it matters:

Small manufacturers often outgrow QuickBooks but aren't ready for a million-dollar ERP. Fishbowl provides the perfect middle ground, allowing American entrepreneurs to stay organized as they grow.

13. Rootstock Cloud ERP

Rootstock is a powerful ERP built entirely on the Salesforce platform, which makes it a top choice for US companies already using Salesforce for their sales and marketing. Because it shares the same database as the CRM, the transition from a "closed sale" to a "production order" is instantaneous. It is designed for complex manufacturing environments, including "Engineer-to-Order" and "Project-Based" manufacturing. The platform leverages the security and global scale of the Salesforce cloud.

- Salesforce Ecosystem Integration: It provides a 360-degree view of the customer, from their first inquiry to the day their custom-built product is shipped from the factory.

- Project Manufacturing: It allows companies to track costs and schedules for specific large-scale projects, which is essential for construction and aerospace industries.

- Capacity Planning: The software analyzes machine and labor availability to provide realistic "Promise Dates" to customers during the sales process.

- Supply Chain Visibility: It includes tools for managing vendor performance and tracking inbound shipments of raw materials across global trade routes.

- Cloud Security: By living on the Salesforce platform, it benefits from world-class security protocols, ensuring that sensitive manufacturing data is always protected.

Pricing:

- Pricing for the Growth tier starts at $120 per user per month, while the Enterprise-grade version is approximately $240 per user per month.

Why it matters:

In the US, "Sales and Operations" are often disconnected. Rootstock brings them together, ensuring that the factory only builds what the sales team is actually selling, reducing wasted effort.

14. Siemens Insights Hub (formerly MindSphere)

Siemens Insights Hub is a cloud-based industrial IoT platform that excels at analyzing data from large fleets of industrial equipment. It is widely used by US automotive and heavy machinery manufacturers to improve the efficiency of their production lines. The platform is known for its "open" architecture, meaning it can collect data from almost any machine, not just those built by Siemens. This makes it a powerful tool for older factories that have a mix of new and legacy equipment.

- Open Connectivity: It supports a wide range of industrial protocols, allowing it to "talk" to almost any PLC (Programmable Logic Controller) or sensor on the floor.

- Advanced Visualizations: Users can create high-quality dashboards that show real-time performance data, energy usage, and quality metrics across multiple global sites.

- App Marketplace: Siemens offers a library of pre-built industrial apps for specific tasks like motor monitoring or energy management, reducing the time to see value.

- Security at Scale: It features robust industrial cybersecurity measures to protect factory data as it moves from the machine to the cloud.

- Digital Transformation Consulting: Siemens often provides expert guidance alongside the software to help US manufacturers rethink their entire business model for the digital age.

Pricing:

- Entry-level connectivity kits can start at $950 per hour for specialized implementation, but enterprise-level subscriptions are typically custom-quoted based on data volume and the number of connected assets.

Why it matters:

Knowledge is power. Insights Hub gives US manufacturers the "knowledge" of exactly how their machines are performing, allowing them to squeeze every bit of efficiency out of their production lines.

15. Plex Manufacturing Cloud

Plex is a "Smart Manufacturing Platform" that was built from the ground up for the cloud. It is unique because it doesn't just manage data; it actually controls the shop floor. It is highly popular in the US automotive and aerospace sectors because of its rigorous quality and compliance features. Plex is known for its "always-on" nature, providing a real-time heartbeat of the entire business from any device. It is a true "shop-floor-to-top-floor" solution.

- Checksheets and Quality Logs: The system requires workers to complete digital quality checks as part of their workflow, making it impossible to skip important safety steps.

- Production Control: It provides a real-time view of every job running on the floor, including who is working on it, which machine is being used, and how many parts have been made.

- Traceability and Compliance: It maintains a "Digital Thread" for every product, allowing companies to trace every component back to its original source in seconds.

- Integrated Maintenance: By linking maintenance directly to production, the system can automatically pause a job if a machine is overdue for a critical safety inspection.

- Customer Portal: It allows manufacturers to give their customers a login to see the status of their orders, improving transparency and trust in the relationship.

Pricing:

- Pricing for the Plex Manufacturing Cloud generally starts at $500 per user per month, depending on the specific modules and volume of production.

Why it matters:

For US industries with strict regulations, like medical devices or defense, Plex provides the "audit-proof" record-keeping needed to stay in business and maintain high quality standards.

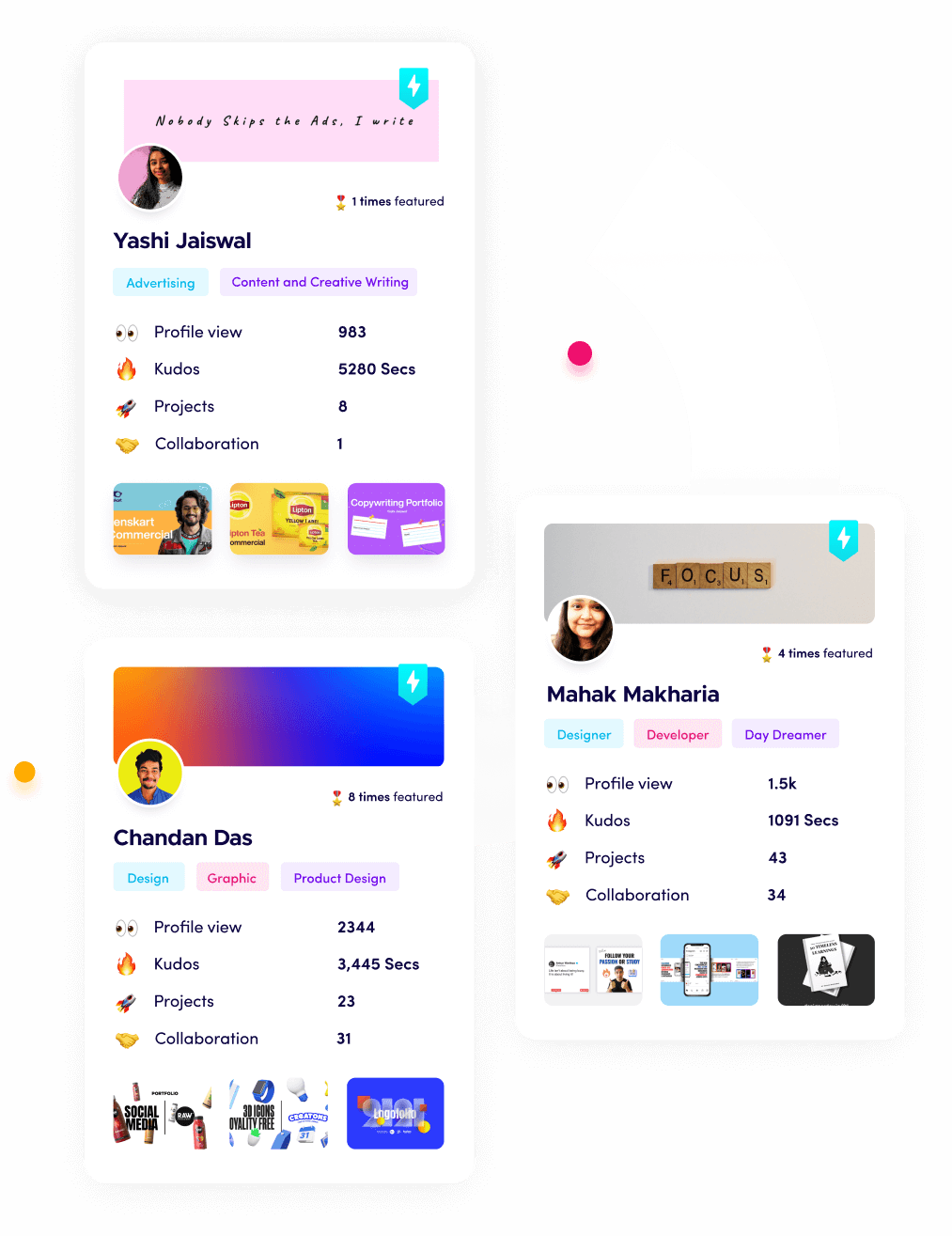

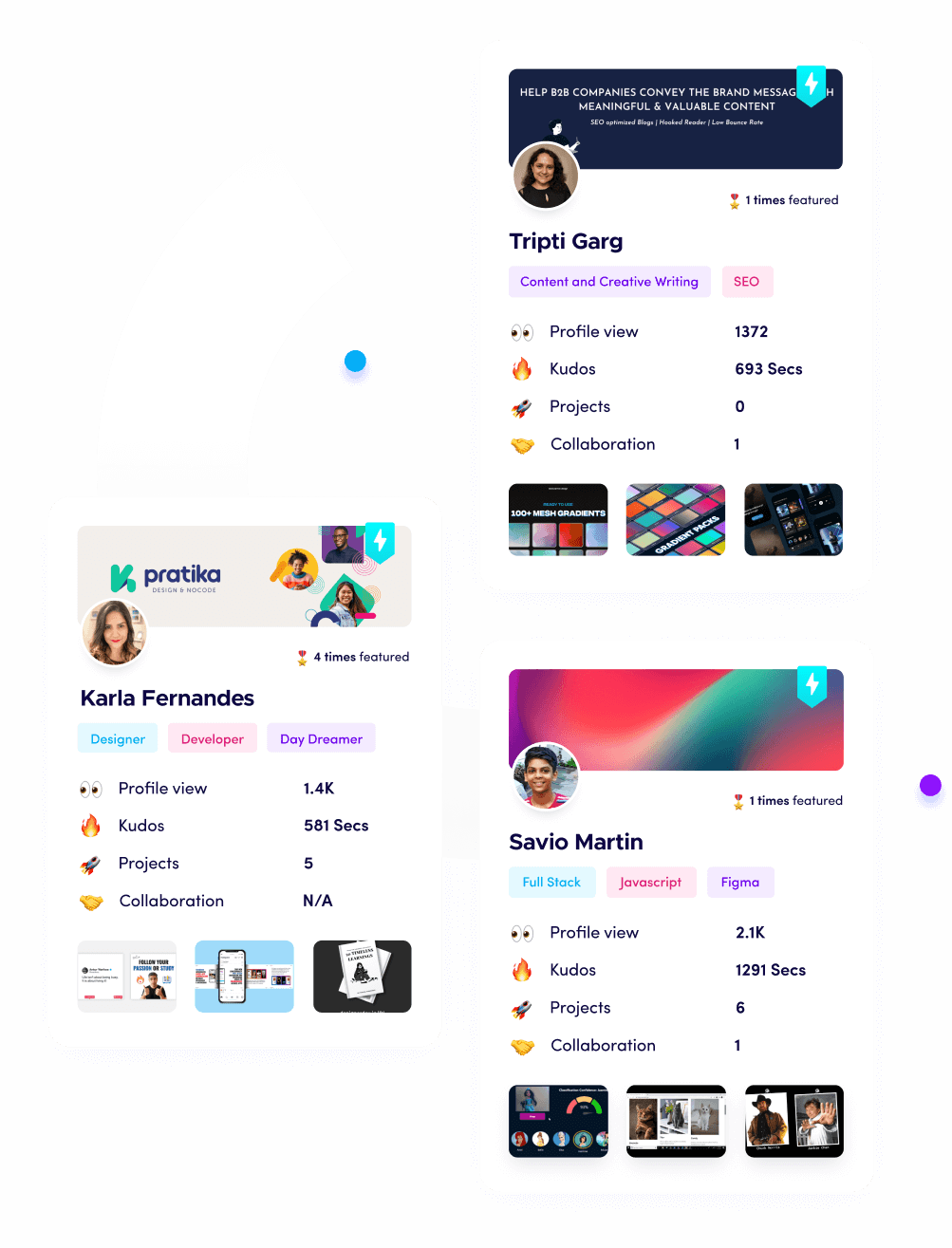

Showcase Your Skills with Fueler

Understanding these 15 tech solutions is only half the battle, the other half is proving you know how to use them. Whether you are an expert in Mastercam, a pro at Odoo implementation, or a specialist in IIoT data analysis, you need a way to show your work to potential employers.

Fueler helps you move beyond the traditional resume by allowing you to create a "proof-of-work" portfolio. Instead of just saying you know "Supply Chain Management," you can upload the specific assignments, project plans, or digital twin simulations you have created. It is the best way for professionals in the manufacturing and tech space to stand out and get hired based on what they can actually do.

Final Thoughts

The future of US manufacturing is digital, and the 15 tools listed above are leading the charge. From no-code platforms like Tulip to heavy-duty control systems like FactoryTalk, these solutions are making American factories smarter, safer, and more efficient. As the industry continues to evolve, the demand for professionals who can navigate these technologies will only grow. Staying updated on these tools and building a strong portfolio of your work will be the key to a successful career in this new industrial era.

FAQs

1. What are the best free tools for manufacturing startups in 2026?

Startups can look at Odoo's "One App Free" plan for basic ERP needs or use the free basic version of MaintainX for maintenance tracking. Additionally, some CAD tools like Fusion have free tiers for hobbyists and educational use which can help in the early design phases of a new product.

2. How do I choose between different ERP systems for a US factory?

The choice depends on your scale and current tech stack. If you are a small business using QuickBooks, Fishbowl is a great fit. If you are already deep in the Microsoft or Salesforce ecosystems, then Dynamics 365 or Rootstock will provide the best integration for your team.

3. Is IIoT technology worth the investment for small machine shops?

Yes, because IIoT tools like PTC ThingWorx or Siemens Insights Hub help prevent the most expensive problem in manufacturing: unplanned downtime. Even a basic sensor setup can save a small shop thousands of dollars by alerting them to a machine failure before it happens.

4. How can I learn to use industrial software like Mastercam or FactoryTalk?

Most of these companies offer specialized certification programs and online academies. You can also find many tutorials on YouTube and through community forums. Once you learn a skill, be sure to document your projects on a platform like Fueler to show your expertise to employers.

5. What is the main benefit of cloud-based manufacturing software?

The primary benefit is real-time collaboration and accessibility. Cloud-based tools like Plex or Katana allow managers to see what is happening on the factory floor from anywhere in the world, ensuring that decisions are made based on the most up-to-date information available.

What is Fueler Portfolio?

Fueler is a career portfolio platform that helps companies find the best talent for their organization based on their proof of work. You can create your portfolio on Fueler. Thousands of freelancers around the world use Fueler to create their professional-looking portfolios and become financially independent. Discover inspiration for your portfolio

Sign up for free on Fueler or get in touch to learn more.