Integrating IoT-Enabled Apps in US Manufacturing: The Ultimate Guide for 2025

Riten Debnath

26 Aug, 2025

American manufacturers are reshaping their industries by turning towards IoT technology—the true bridge between digital insight and physical production. Integrating IoT-enabled applications isn’t just about tracking machines; it’s about increasing efficiency, safety, and profitability in a market where every percentage of improvement matters. In 2025, those who master IoT integration will pull ahead in productivity, traceability, and innovation.

I’m Riten, founder of Fueler, a platform that helps US manufacturers and tech leaders hire proven IoT app talent through assignment-based evaluations. In this comprehensive guide, I’ll show you how IoT-enabled apps are revolutionizing US plants and supply chains, and what to prioritize in your integration strategy. Just like a powerful portfolio demonstrates your ability and trust, a smart IoT app strategy is proof you’re ready for the next era of manufacturing excellence.

Understanding IoT-Enabled Apps in the Manufacturing Context

IoT (Internet of Things) apps connect sensors, machinery, workers, and data systems, enabling real-time monitoring, automation, and data-driven decisions on the shop floor. These apps empower manufacturers with visualizations, alerts, predictive analytics, and remote control features that dramatically reduce downtime and optimize operations.

- Aggregate live data from machines, production lines, and environmental sensors for instant feedback.

- Enable remote monitoring and troubleshooting, even across multiple plants or locations.

- Trigger automated responses to anomalies, cutting downtime and preventing hazards.

- Seamlessly integrate with MES, ERP, and cloud platforms for unified business oversight.

Why it matters: Using IoT-enabled apps in US manufacturing means you get timely visibility, react faster to problems, and gain precise control over resource usage—giving you an edge in a fiercely competitive market. Additionally, combining these apps with pipe fabrication software can further streamline production workflows and reduce manual errors.

1. Improved Monitoring and Predictive Maintenance

By integrating IoT-enabled apps, manufacturers can achieve proactive maintenance and real-time asset monitoring. Sensors on equipment provide live updates on temperature, vibration, utilization, and wear, alerting teams to emerging problems before breakdowns occur.

- 24/7 automated monitoring of all critical equipment.

- Predictive alerts based on data trends, not just scheduled checks.

- Reduced unscheduled downtime and lower repair costs.

Why it matters: Predictive maintenance keeps US production lines running smoothly, boosting output and conserving maintenance budgets by avoiding costly emergencies.

2. Enhanced Production Efficiency and Automation

IoT apps can identify bottlenecks and inefficiencies on the factory floor in real time. When paired with machine learning, these systems not only highlight issues but adjust workflows on the fly maximizing throughput and minimizing defects.

- Real-time KPIs and dashboards for operators and managers.

- Automation of repetitive or error-prone tasks.

- Data-driven adjustments to production processes for better yield.

Why it matters: Increasing process efficiency with IoT is a proven path for US manufacturers to reduce waste, raise quality, and stay price-competitive even with rising labor or material challenges.

3. Advanced Quality Control and Traceability

Modern IoT-enabled systems can track each product across its journey in the plant, ensuring quality assurance from raw input to final delivery. Image sensors, smart cameras, and RFID tags automatically log data that would otherwise require manual entry.

- End-to-end traceability with digital records for every unit.

- Automated quality control checks with instant feedback and alerts.

- Faster root-cause analysis for defects or recalls.

Why it matters: Superior traceability and QA give US businesses proof of compliance—crucial for regulated sectors and help retain consumer trust with transparent operations.

4. Worker Safety and Environment Monitoring

IoT devices monitor environmental conditions (air quality, heat, humidity) and worker movements, creating safer workspaces and reducing liability. Mobile apps and wearables can instantly alert staff to hazards or machine malfunctions.

- Live environmental alerts and automated safety shutdowns.

- Wearable devices track location and health metrics.

- Compliance with OSHA and other US safety standards.

Why it matters: Enhanced safety through IoT safeguards US workers, cuts insurance risks, and builds a reputation for responsible manufacturing.

5. Integration with MES, ERP, and Cloud Analytics

IoT-enabled apps don’t live in silos they must connect with existing systems like Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP), and cloud analytics for maximum value. The seamless integration enables data-sharing and smarter business decisions.

- Open APIs and standardized communication protocols (MQTT, OPC-UA, REST).

- Real-time data sync with ERP systems for inventory and finance.

- Cloud analytics dashboards accessible from anywhere.

Why it matters: Integrated IoT solutions turn isolated data into actionable intelligence, allowing US manufacturers to optimize at both the machine and executive level.

How to Plan IoT App Integration for US Manufacturing

A successful implementation calls for strategy:

- Map your current infrastructure, machines, and manual data entry points.

- Prioritize high-impact areas (e.g., critical machinery, compliance touchpoints, labor-intensive processes).

- Choose IoT hardware and software partners with strong US market presence and references.

- Run pilot projects and measure ROI before scaling plant-wide.

- Train staff to use mobile dashboards, alerts, and analytic tools.

Why it matters: Careful planning avoids costly disruptions and ensures your IoT investment delivers results from day one.

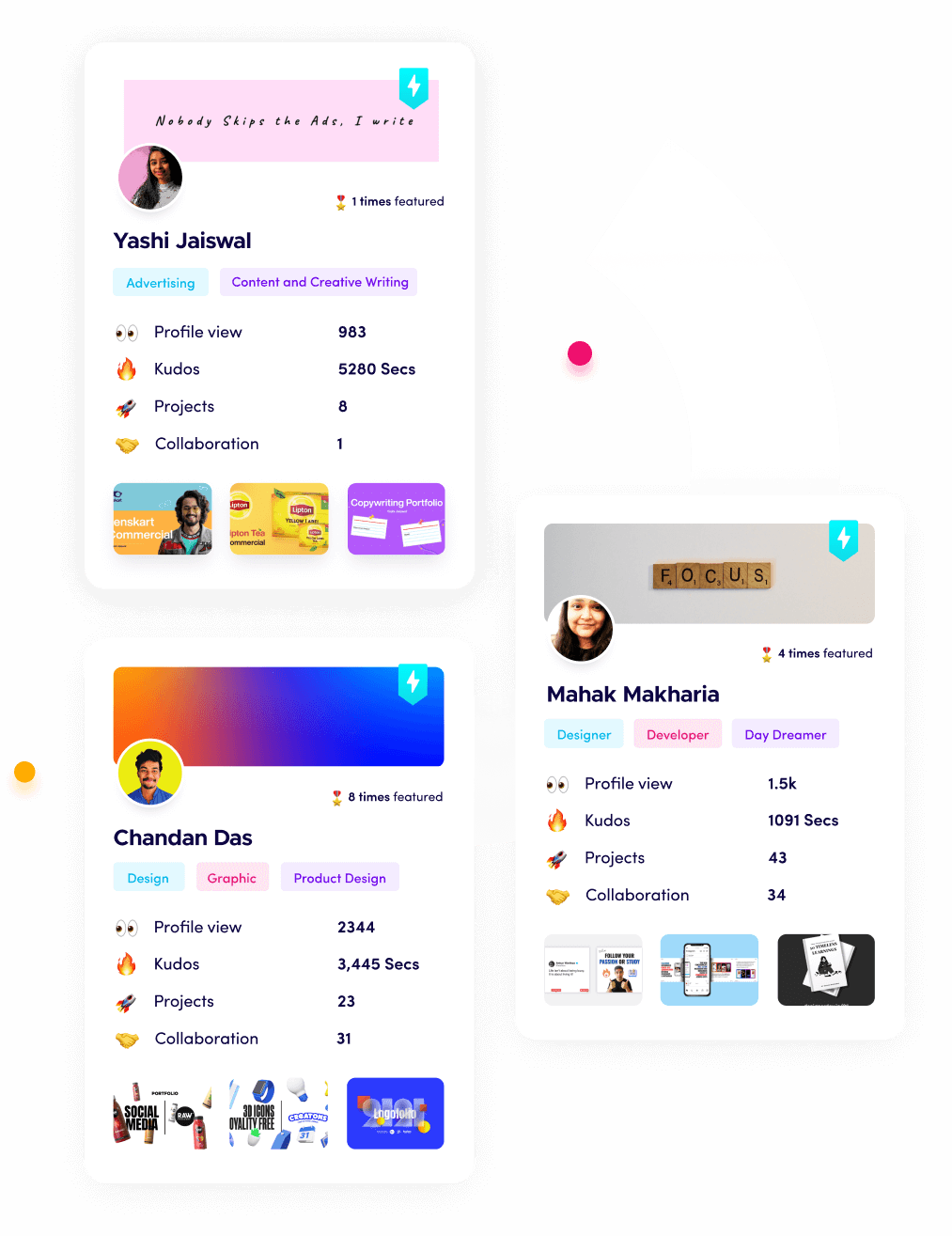

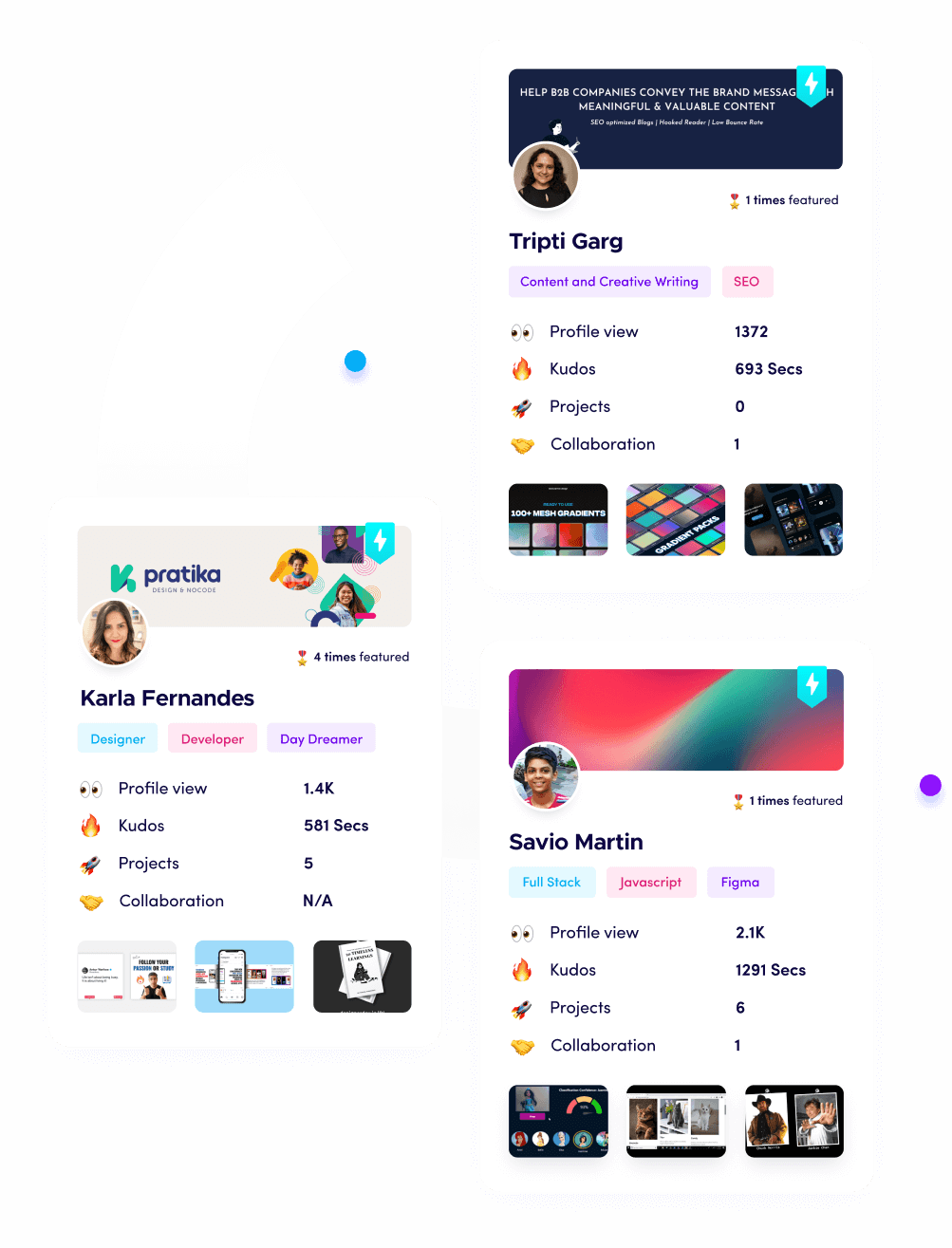

Fueler: Streamline Your IoT Talent Acquisition

The true value from IoT integration comes from experienced professionals who’ve delivered real manufacturing results. Fueler lets you hire top IoT app developers, data engineers, and project managers by assigning real-life projects or proof-of-concept tasks, reviewing candidates’ output before hiring.

- Post your IoT integration challenge as an assignment.

- Evaluate candidates based on their real-world solutions.

- Ensure you hire pros who know how to deliver US manufacturing outcomes, not just generic IoT knowledge.

Why it matters: Assignment-based hiring with Fueler ensures your IoT projects are staffed by experts who can hit the ground running, reducing errors and maximizing operational gains.

Final Thought

In 2025, integrating IoT-enabled apps is no longer a futuristic vision for US manufacturing—it’s the standard for staying competitive, agile, and resilient. With the right technology, proven talent, and thoughtful planning, IoT delivers unprecedented levels of efficiency, quality, and safety. Use platforms like Fueler to build your expert team, and position your organization at the forefront of American manufacturing for years to come.

FAQs: Integrating IoT-Enabled Apps in US Manufacturing

1. What is the biggest advantage IoT-enabled apps bring to US manufacturing?

They enable real-time monitoring and predictive maintenance, helping plants reduce downtimes and increase asset life.

2. How do IoT apps improve production efficiency on the factory floor?

By gathering and analyzing live data, IoT systems identify inefficiencies and optimize processes automatically for higher throughput and reduced waste.

3. What security challenges should US manufacturers consider with IoT?

Ensuring device and network security, regular software updates, and compliance with US data protection laws (like CCPA) is critical to prevent breaches.

4. Can IoT-enabled apps help with factory worker safety?

Yes, they can monitor environmental hazards, send instant alerts, and track worker conditions to meet OSHA requirements and reduce onsite risks.

5. Where can I find experienced professionals to implement IoT in manufacturing?

Platforms like Fueler allow US manufacturers to assign IoT projects as tests, letting you hire only those with proven, practical results in real-world settings.

What is Fueler Portfolio?

Fueler is a career portfolio platform that helps companies find the best talents for their organization based on their proof of work.

You can create your portfolio on Fueler, thousands of freelancers around the world use Fueler to create their professional-looking portfolios and become financially independent. Discover inspiration for your portfolio

Sign up for free on Fueler or get in touch to learn more.