Integrating IoT-Enabled Apps in European Manufacturing

Riten Debnath

29 Aug, 2025

Are you ready to discover how IoT-enabled apps are changing factories across Europe? Manufacturing is going through a major digital shift, with smart technologies bringing efficiency, better quality, and real-time insights. Today, integrating IoT apps is the key step every factory must consider to stay ahead in this technology race.

I’m Riten, founder of Fueler, a platform helping freelancers and professionals get hired through their project work. In this article, I’m explaining the huge impact IoT-enabled apps are having on European manufacturing. But just having the apps isn’t enough. The way you present your successful projects matters most. Your portfolio is your record of real impact, your trust builder, and the shortest path to leadership in this fast-evolving field.

How IoT-Enabled Apps are Transforming Manufacturing in Europe

IoT (Internet of Things) apps bring together sensors, machines, dashboards, and data analytics. These apps connect machine tools, assembly lines, and even warehouses, sharing information in real time. By 2025, thousands of factories from automotive to food processing rely on IoT-enabled solutions for smarter decisions, predictive maintenance, and reduced downtime.

- Real-time monitoring of equipment health and performance

- Automated data collection from production lines

- Faster fault detection for reduced breakdowns

- Improved resource and energy management

Why it Matters: Using IoT in this space means European manufacturers gain new visibility, take quicker action, and eliminate costly surprises. It directly boosts productivity and profits.

Key Benefits of Integrating IoT-Enabled Apps

Bringing IoT apps into manufacturing is about more than just adding gadgets. The true value is in the results of automatic alerts, better planning, and connected teams that work smarter.

- Predicts potential failures before they cause problems

- Cuts unnecessary energy usage with smart controls

- Automates inventory management and ordering

- Allows for remote control and diagnostics

Why it Matters: With these benefits, every company in this sector can solve old problems with modern tools and unlock growth rapidly.

Popular Use Cases of IoT Apps in European Factories

Every factory is different, but many use IoT-enabled apps for similar challenges. Whether it’s tracking machines, improving worker safety, or securing supply chains, the list keeps growing.

- Machine health monitoring and predictive maintenance

- Automated quality checks with real-time reporting

- Smart warehouse and logistics management

- Worker safety through smart wearables and alerts

Why it Matters: Effective use of IoT in this field means tangibly reducing costs, improving safety, and delivering higher-quality products.

Implementation Challenges: What to Watch Out For

Switching to IoT can be complex. Factories must upgrade systems, train teams, and tackle data security. Skilled partners who understand both manufacturing and tech make a big difference.

- Integrating new IoT apps with old machines

- Ensuring strong cybersecurity for all devices

- Managing the huge volume of platform data

- Regular training for staff and IT teams

Why it Matters: Addressing these challenges is critical for smooth upgrades and long-term usefulness of IoT investments in European factories.

The Future: AI Meets IoT in Manufacturing

The next wave is the fusion of AI (Artificial Intelligence) and IoT. This powerful mix moves from simple monitoring to AI-based predictions, fully automated processes, and smart issue resolutions well beyond what humans alone can achieve.

- Intelligent scheduling for maintenance and repairs

- Adaptive production lines reacting to real-time changes

- Automated supply chain snapshots and forecasting

- Personalized recommendations for decision makers

Why it Matters: The combination sets the stage for self-optimizing factories, empowering companies with tools that help lead the global market in efficiency and innovation.

Why Your Work Portfolio is Now Essential

Building great IoT projects is important, but showing them off matters more for your growth. In today’s competitive environment, a strong work portfolio proves you can deliver real impact not just theory.

- Show real-world IoT projects and measurable results

- Demonstrate problem-solving on complex factory floors

- Stand out for assignments and new client opportunities

- Instantly build credibility and partnership trust

Why it Matters: In this process, a solid portfolio opens doors, wins contracts, and lets you showcase expertise in the fiercely competitive world of manufacturing tech.

Pro Tip: To be discovered for top IoT projects, use Fueler. The platform allows you to present your best IoT-enabled manufacturing solutions through real case studies, helping companies hire through proven assignments rather than just resumes.

Steps to Get Started with IoT Apps in Manufacturing

For companies just beginning their IoT journey, success starts with a clear strategy. Taking a phased, well-planned approach helps avoid frustration and costly missteps.

- Begin with small pilot projects before factory-wide rollout

- Identify the best use cases: maintenance, energy, logistics

- Connect with experienced IoT solution providers

- Focus on employee training and support throughout

Why it Matters: This approach ensures every move in integrating IoT apps delivers maximum value—step by step, challenge after challenge.

Building Long-Term Digital Advantage in Manufacturing

European factories can’t afford to stop at a single upgrade. The goal is a continuous digital transformation, embracing constant learning and adapting to new technologies as they emerge.

- Update IoT platforms and devices with regular software upgrades

- Expand integration to include supply chain and customer feedback

- Review progress, measure ROI, and improve processes regularly

- Upskill staff in the latest digital trends

Why it Matters: Focusing on sustained digital advantage turns manufacturing from a cost center into a growth engine for the future.

Final Thought

Integrating IoT-enabled apps in European manufacturing is no longer a choice—it’s a necessity for any company aiming to compete globally. The smart use of these tools means fewer breakdowns, better products, and happier customers. Success in this field goes beyond technology. Showcasing your biggest wins through a portfolio proves your value and opens up new opportunities, whether for new projects or exciting job assignments.

Frequently Asked Questions

1. What are the biggest benefits of IoT apps for European manufacturers?

Real-time monitoring, predictive maintenance, energy savings, and quality control are top gains for factories using IoT apps.

2. How do companies choose the right IoT app for their needs?

Start with a business audit, define your biggest pain points, and then select IoT solutions that address those specific challenges.

3. What security concerns come with IoT integration in factories?

Key risks include device hacking, data breaches, and unprotected networks. Always ensure devices have strong encryption and are managed by qualified teams.

4. How much do IoT-enabled app solutions typically cost?

Costs vary based on project size, hardware requirements, and necessary integrations. Pilot projects start small, while large plant-wide rollouts need bigger budgets and ongoing support.

5. Why is a portfolio important for IoT professionals in manufacturing?

Real work samples and case studies prove expertise, help win contracts, and establish trust with partners and employers.

What is Fueler Portfolio?

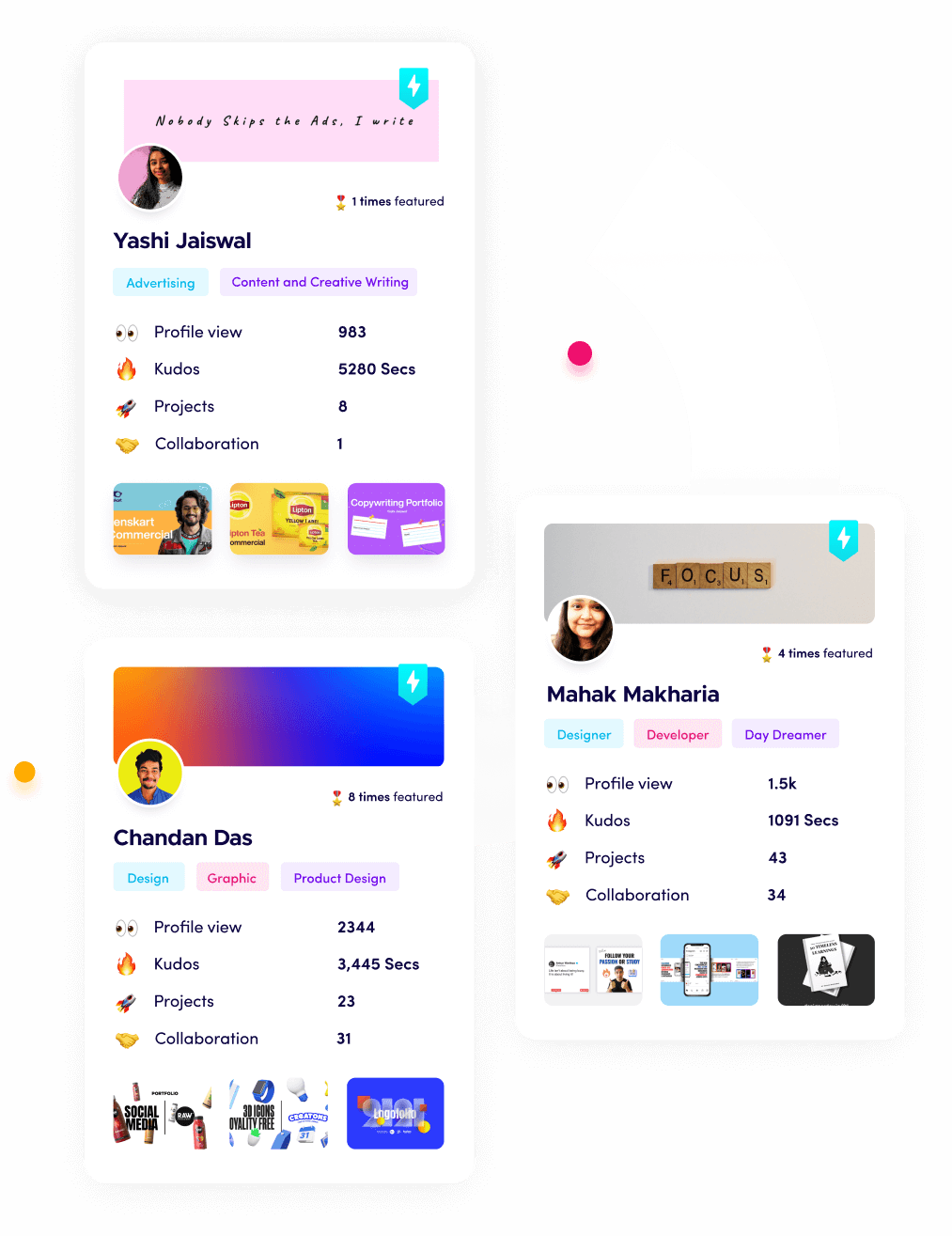

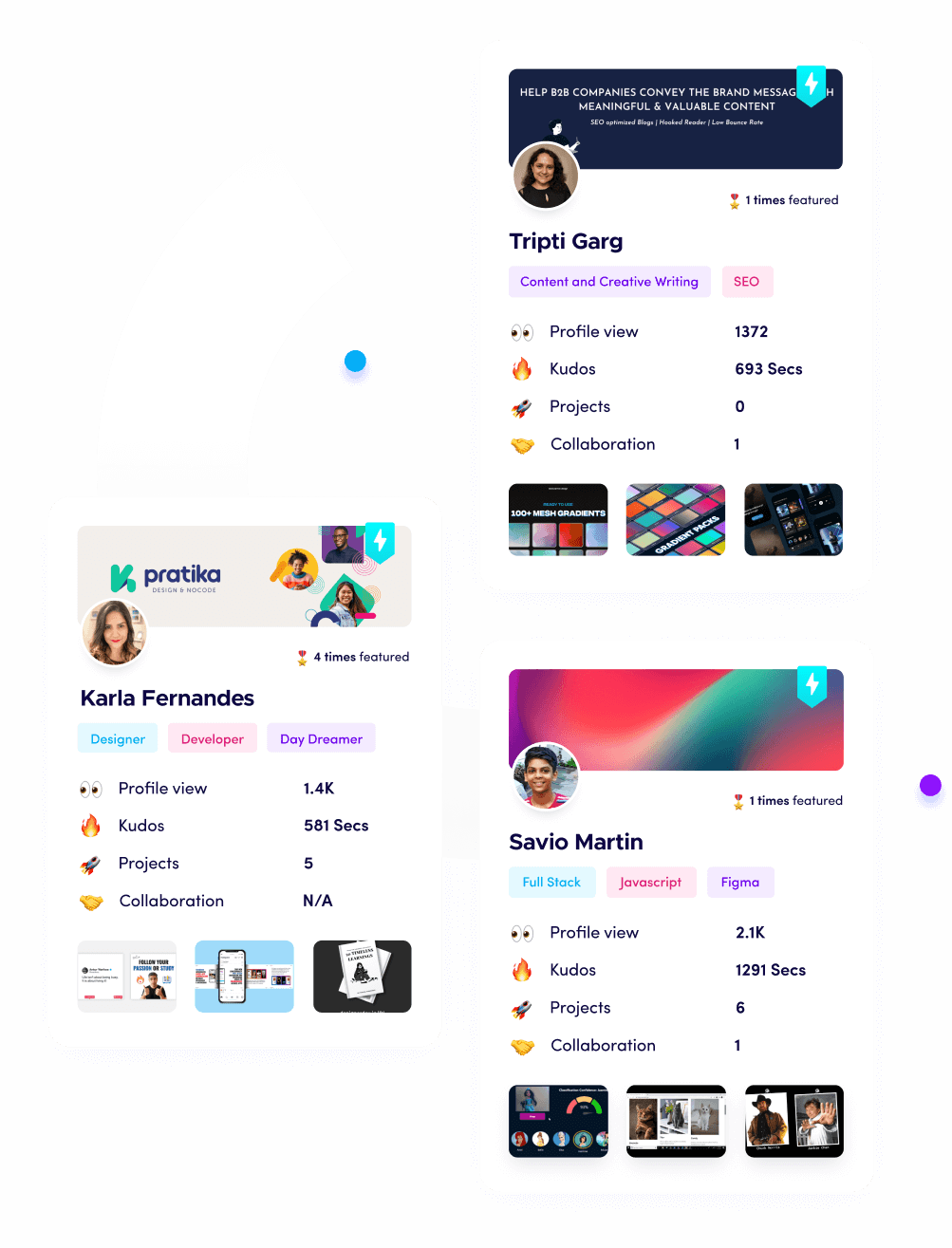

Fueler is a career portfolio platform that helps companies find the best talents for their organization based on their proof of work.

You can create your portfolio on Fueler, thousands of freelancers around the world use Fueler to create their professional-looking portfolios and become financially independent. Discover inspiration for your portfolio

Sign up for free on Fueler or get in touch to learn more.