How Modernizing Legacy Apps Enhances Agility in Manufacturing

Riten Debnath

22 Oct, 2025

Manufacturing today faces a relentless demand for rapid innovation, flexible production, and real-time responsiveness in a globally competitive market. Unfortunately, legacy applications built on outdated technology cannot keep pace with these demands. Aging systems hinder agility, slow down workflows, and restrict innovation. Modernizing these legacy apps is essential in 2026 to remove these barriers and transform manufacturing operations into nimble, data-driven, and future-ready systems with accelerated time to market and enhanced customer responsiveness.

I’m Riten, founder of Fueler, a platform that helps freelancers and professionals get hired through their work samples. In this article, I’ll walk you through how modernizing legacy apps enhances agility in manufacturing. You can master the required skills, but presenting your expertise smartly is equally crucial. Your portfolio is not just a collection of projects; it's your proof of skill, credibility, and your shortcut to trust.

Let's explore the deep strategic and operational impacts of legacy modernization in manufacturing.

Understanding the Constraints Imposed by Legacy Systems

Legacy apps in manufacturing are often monolithic, rigid, and poorly integrated with modern tools. They come with significant technical debt costly to maintain, hard to scale, and lacking flexibility to adapt to new business models.

- Legacy systems typically run on outdated hardware or software stacks, increasing downtime risks and inefficiencies.

- They create data silos, preventing real-time insights due to poor interoperability with newer systems like IIoT or cloud platforms.

- Inflexible architectures hinder rapid deployment of new features or process optimizations.

- Skills to support legacy languages and frameworks are scarce, driving up support costs and extending issue resolution times.

Why it matters: Legacy systems limit manufacturers’ ability to respond swiftly to market disruptions, hampering competitiveness and growth.

Accelerating Innovation Through Modern Architectures

Modernizing legacy applications involves transitioning from monoliths to modular, cloud-native microservices architectures that promote flexibility, scalability, and rapid innovation.

- Microservices break large applications into smaller, independently deployable components, enabling parallel development and quicker feature releases.

- Cloud platforms provide elastic resources, scaling compute and storage based on production demand or analytics workloads.

- APIs and integration bridges connect legacy data and processes with modern enterprise systems, IoT platforms, and analytics tools.

- Containerization and orchestration tools like Docker and Kubernetes streamline deployment and enhance system resilience.

Why it matters: Modern architectures empower manufacturers to innovate faster, deliver personalized products, and adopt advanced technologies like AI seamlessly.

Enhancing Operational Efficiency and Reducing Costs

Legacy app modernization delivers significant operational benefits, reducing maintenance costs and improving system performance.

- Cloud migration eliminates the need for costly on-premises infrastructure and the risks of hardware failures.

- Automated testing and CI/CD pipelines accelerate software delivery, reducing manual errors and operational disruptions.

- Refactoring legacy code improves application responsiveness and scalability, enabling real-time production adjustments.

- Consolidated systems reduce complexity in IT environments, lowering support costs and knowledge silos.

Why it matters: Lower operational expenses and improved system reliability enable manufacturers to reallocate budgets to strategic initiatives, increasing overall efficiency.

Enabling Data-Driven Manufacturing and Real-Time Insights

Modernized legacy systems integrated with cloud and analytics platforms unlock the potential of manufacturing data for operational excellence.

- Real-time monitoring systems capture machine performance and production data, helping predict failures and optimize scheduling.

- Integrated analytics platforms identify bottlenecks, quality issues, and efficiency opportunities, enabling continuous process improvements.

- Data democratization through accessible dashboards empowers teams at all levels to make informed, proactive decisions.

- Predictive and prescriptive analytics help in demand forecasting, inventory management, and adaptive maintenance routines.

Why it matters: Data-driven operations improve throughput quality, reduce waste, and enhance agility in responding to market and customer needs.

Driving Business Agility Through Enhanced Customer and Market Responsiveness

Modern legacy applications enable manufacturers to bring new products to market faster and tailor manufacturing lines to customer demands dynamically.

- Agile software systems support rapid configuration changes in production lines for custom or small-batch manufacturing.

- Integration with digital twins and simulation tools accelerates product testing and process validation.

- Real-time customer feedback loops integrate with manufacturing operations to refine quality and delivery processes.

- Cloud-based ERP and CRM integrations streamline order processing, supply chain coordination, and after-sales support.

Why it matters: Enhanced market responsiveness drives customer satisfaction, opens new revenue streams, and strengthens competitive positioning.

Fueler: Showcase Your Legacy Modernization and Manufacturing Digital Skills

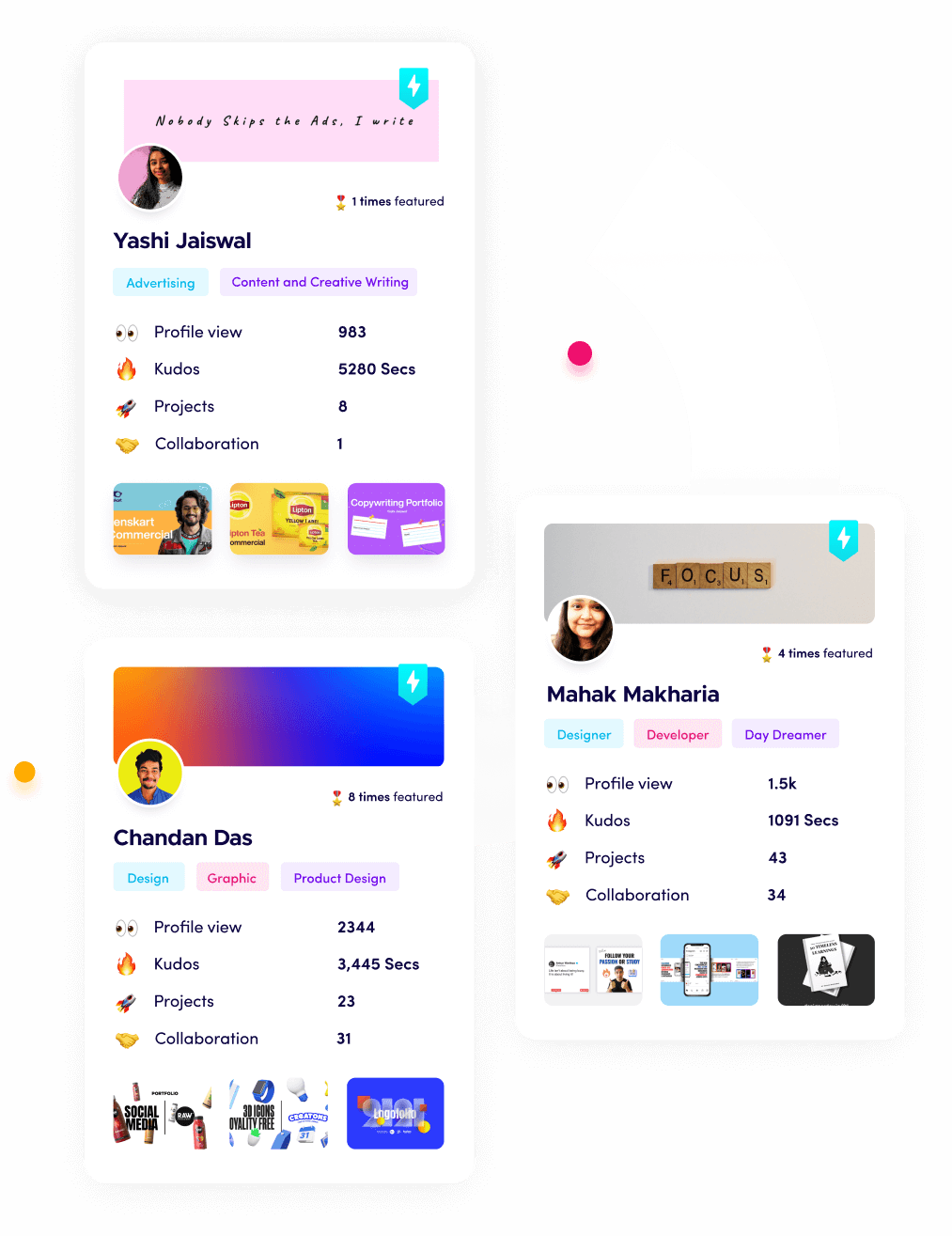

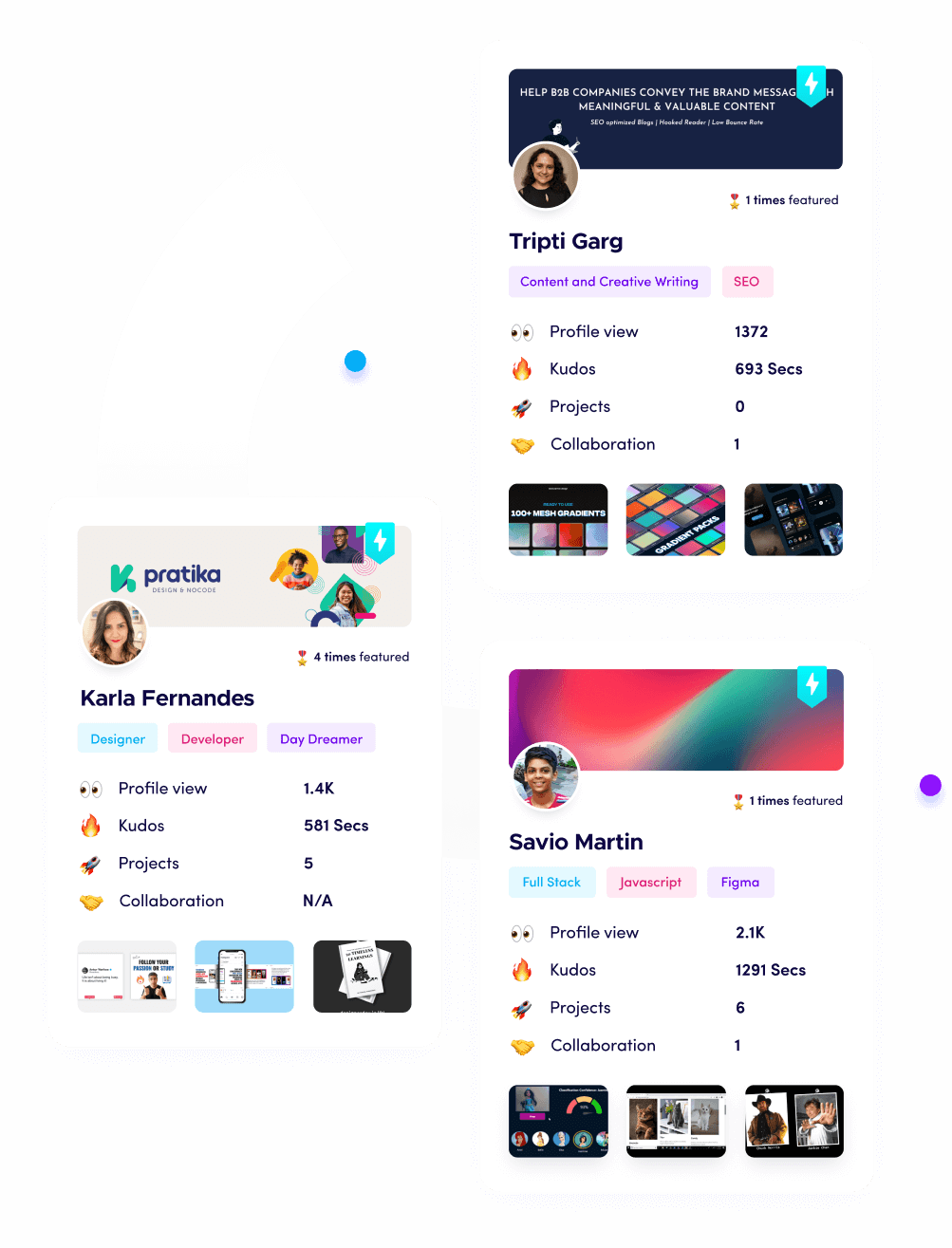

As manufacturing digital transformation intensifies, professionals skilled in legacy modernization and cloud integration are in demand. Fueler helps you create a verified portfolio of your modernization projects, demonstrating your expertise and accelerating your career growth.

Final Thoughts

Modernizing legacy applications is no longer optional for manufacturers aspiring to lead in 2026 and beyond. It unlocks agility, operational efficiency, innovation, and market responsiveness critical to thriving in today’s dynamic manufacturing landscape. Professionals mastering this domain and showcasing their work strategically will be the driving force behind the manufacturing revolution.

FAQs

1. Why is legacy application modernization critical for manufacturing agility?

Legacy systems are rigid and costly, limiting rapid innovation and market responsiveness.

2. How do modern architectures improve manufacturing applications?

They enable scalability, modularity, rapid deployments, and integration with new technologies through microservices and cloud platforms.

3. What operational efficiencies come from modernizing legacy apps?

Reduced costs, better system performance, automated delivery, and simplified IT environments.

4. How does modernization support data-driven manufacturing?

By unlocking real-time data access, analytics, and predictive insights across operations.

5. How does modernization enhance customer and market responsiveness?

By enabling flexible production, faster product launches, and integrated customer feedback for continuous improvement.

What is Fueler Portfolio?

Fueler is a career portfolio platform that helps companies find the best talent for their organization based on their proof of work. You can create your portfolio on Fueler, thousands of freelancers around the world use Fueler to create their professional-looking portfolios and become financially independent. Discover inspiration for your portfolio

Sign up for free on Fueler or get in touch to learn more.