How European Manufacturing Companies Can Adopt IoT

Riten Debnath

28 Nov, 2025

The Internet of Things (IoT) is revolutionizing manufacturing across Europe, offering new ways to connect machines, processes, and people for smarter, more efficient operations. By adopting IoT, European manufacturers can increase productivity, reduce costs, enhance product quality, and improve sustainability. This transformation is part of the Industry 4.0 wave that is reshaping how factories operate worldwide. Successfully adopting IoT requires choosing the right technologies, understanding key benefits, and preparing for challenges such as security and workforce skills.

I’m Riten, founder of Fueler - a skills-first portfolio platform that connects talented individuals with companies through assignments, portfolios, and projects not just resumes/CVs. Think Dribbble/Behance for work samples + AngelList for hiring infrastructure

What Is IoT and Its Importance for Manufacturing

IoT is a network of connected physical devices embedded with sensors, software, and communication technologies that collect and exchange data. In manufacturing, IoT enables real-time monitoring and control of machines and processes, which leads to improved operational decision-making and efficiency.

- IoT systems collect data from machinery to monitor conditions such as temperature, vibration, and usage patterns, detecting issues before they cause failures.

- Connected devices enable remote management of production lines, reducing the need for manual inspections and enabling quick responses to anomalies.

- Data insights gathered through IoT support optimization of processes, reducing waste and energy consumption while enhancing production speed.

- Integration with cloud platforms allows advanced analytics and machine learning applications to predict maintenance needs and optimize asset usage.

- IoT automates control processes such as adjusting machine speeds or calibrations based on real-time data, improving product quality consistency.

- Connected supply chains become more transparent and responsive as IoT tracks materials and finished goods across stages.

- Enhanced data visibility supports compliance with regulatory standards and certifications through automated record-keeping.

Why it matters: Understanding IoT fundamentals is essential for European manufacturers aiming to harness technology to improve operational efficiency and compete globally.

Key Benefits of IoT Adoption in European Manufacturing

IoT adoption presents multiple advantages that address core industrial challenges in Europe, such as high energy costs, strict regulations, and competitive pressure in global markets.

- Proactive maintenance reduces unplanned downtime and extends machinery lifespan by analyzing sensor data to predict failures.

- Real-time production data allows manufacturers to respond quickly to bottlenecks or quality issues, improving throughput.

- Energy monitoring systems reduce utility bills and carbon footprints by dynamically optimizing resource use across facilities.

- Better supply chain integration leads to just-in-time inventory management and improved delivery accuracy.

- Increased automation frees workers from repetitive tasks, improving safety and enabling a focus on higher-value activities.

- Data-driven quality control enhances product consistency and reduces defects, meeting stringent European quality standards.

- Remote monitoring and management enable business continuity during disruptions by controlling equipment from any location.

Why it matters: These benefits empower European manufacturers to improve competitiveness, comply with sustainability goals, and boost overall profitability

Choosing the Right IoT Platforms for European Manufacturing

Selecting an IoT platform is a critical decision that impacts scalability, security, and performance. The right platform enables seamless integration of devices, real-time analytics, and easy customization.

- Platforms like Siemens MindSphere offer comprehensive industrial IoT solutions built for European manufacturing standards.

- Bosch IoT Suite focuses on device management, connectivity, and analytics tailored for factory environments.

- PTC ThingWorx is known for rapid deployment and flexibility, catering to diverse manufacturing applications.

- IBM Watson IoT provides AI-driven insights to optimize operations and predictive maintenance.

- SAP Leonardo integrates IoT with enterprise resource planning for holistic workflow management.

- Microsoft Azure IoT offers scalable, cloud-based solutions with extensive cybersecurity features.

- GE Predix specializes in industrial-grade IoT designed to handle complex manufacturing processes.

Why it matters: Choosing a robust IoT platform ensures manufacturers can scale smart solutions securely while adapting quickly to evolving needs.

Implementing IoT Sensors and Devices for Real-Time Monitoring

IoT sensors form the backbone of smart manufacturing by continuously capturing critical data on machine health and environmental conditions.

- High-precision sensors measure temperature, humidity, vibration, and pressure to detect anomalies early.

- Wireless sensors enable flexible installation without disrupting operations, ideal for legacy systems.

- Edge computing devices process data locally, reducing latency and bandwidth usage for faster decision-making.

- Integration with cloud platforms facilitates centralized monitoring and advanced analytics.

- Automated alerts notify teams proactively about potential issues, minimizing downtime.

- Sensors with self-diagnostic capabilities enhance reliability and maintenance planning.

- Power-efficient sensors contribute to sustainable operations by lowering energy consumption.

Why it matters: Proper sensor deployment is essential for accurate data collection, enabling timely intervention and continuous process improvement.

Data Security and Compliance in Industrial IoT

Connecting manufacturing environments to the internet creates new cybersecurity challenges. Protecting sensitive data and complying with regulations is paramount.

- End-to-end data encryption safeguards information during transmission and storage.

- Multi-factor authentication limits access to authorized personnel only.

- Regular security patching and updates prevent exploitation of vulnerabilities.

- Network segmentation containing IoT devices mitigates the impact of cyberattacks.

- Compliance with GDPR and industry-specific standards ensures legal and ethical operations.

- Real-time threat monitoring enables rapid response to security incidents.

- Vendor security certifications provide assurance on third-party platform reliability.

Why it matters: Ensuring strong cybersecurity protects intellectual property, maintains regulatory compliance, and preserves customer trust.

Building Skills and Culture for IoT Success

Successful IoT adoption needs skilled workers and a culture open to innovation. This includes training and change management.

- Upskilling employees with IoT system operation and data interpretation fosters smoother implementations.

- Cross-department collaboration breaks silos between IT and production teams.

- Leadership commitment drives a digital-first mindset and allocates necessary resources.

- Change management programs address workforce concerns and ease technology adoption.

- Encouraging experimentation with IoT pilots helps identify best practices.

- Collaborations with technology partners accelerate knowledge transfer.

- Continuous learning programs keep teams updated on evolving IoT trends.

Why it matters: Developing the right skills and culture unlocks IoT’s full potential by ensuring technology is embraced and effectively utilized.

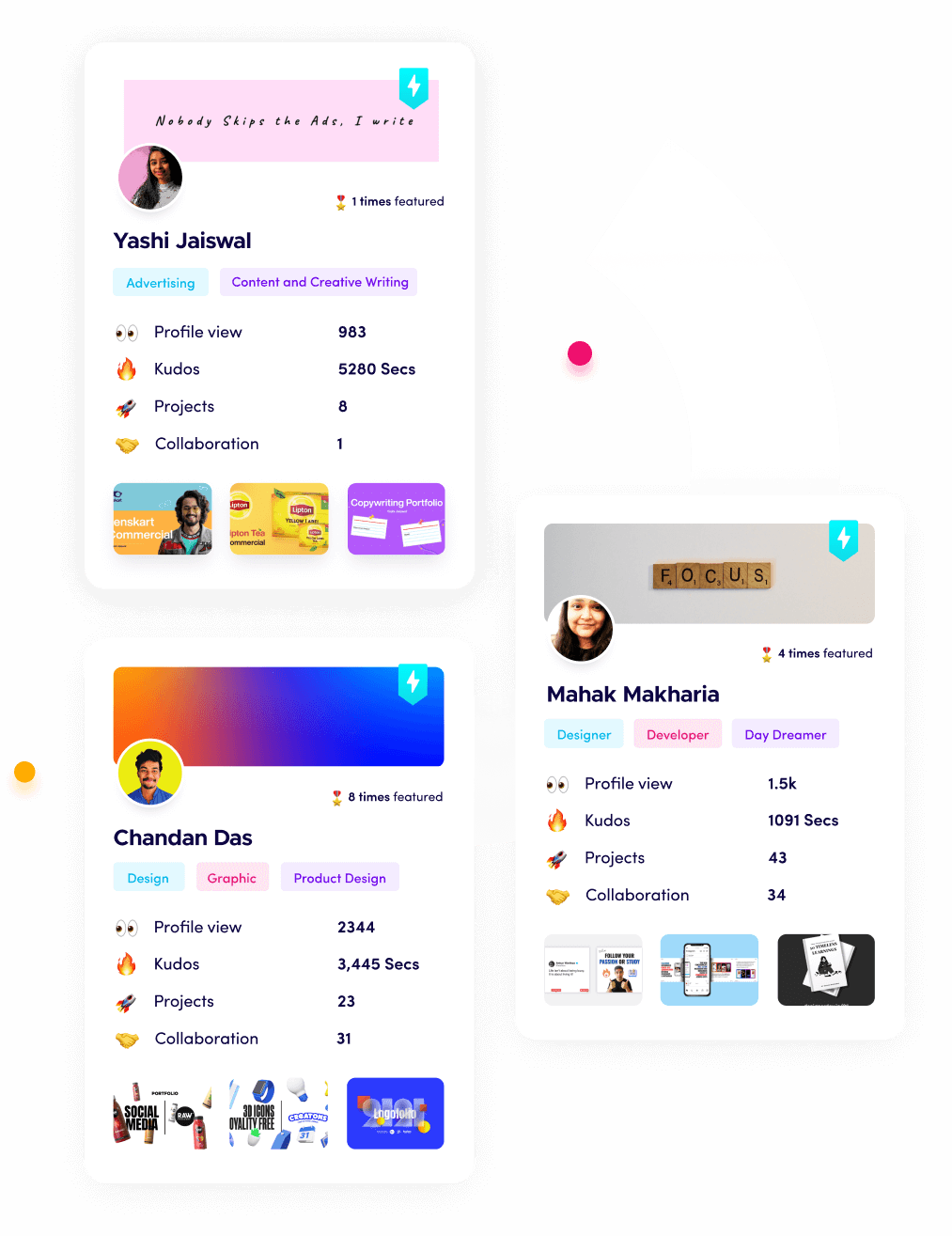

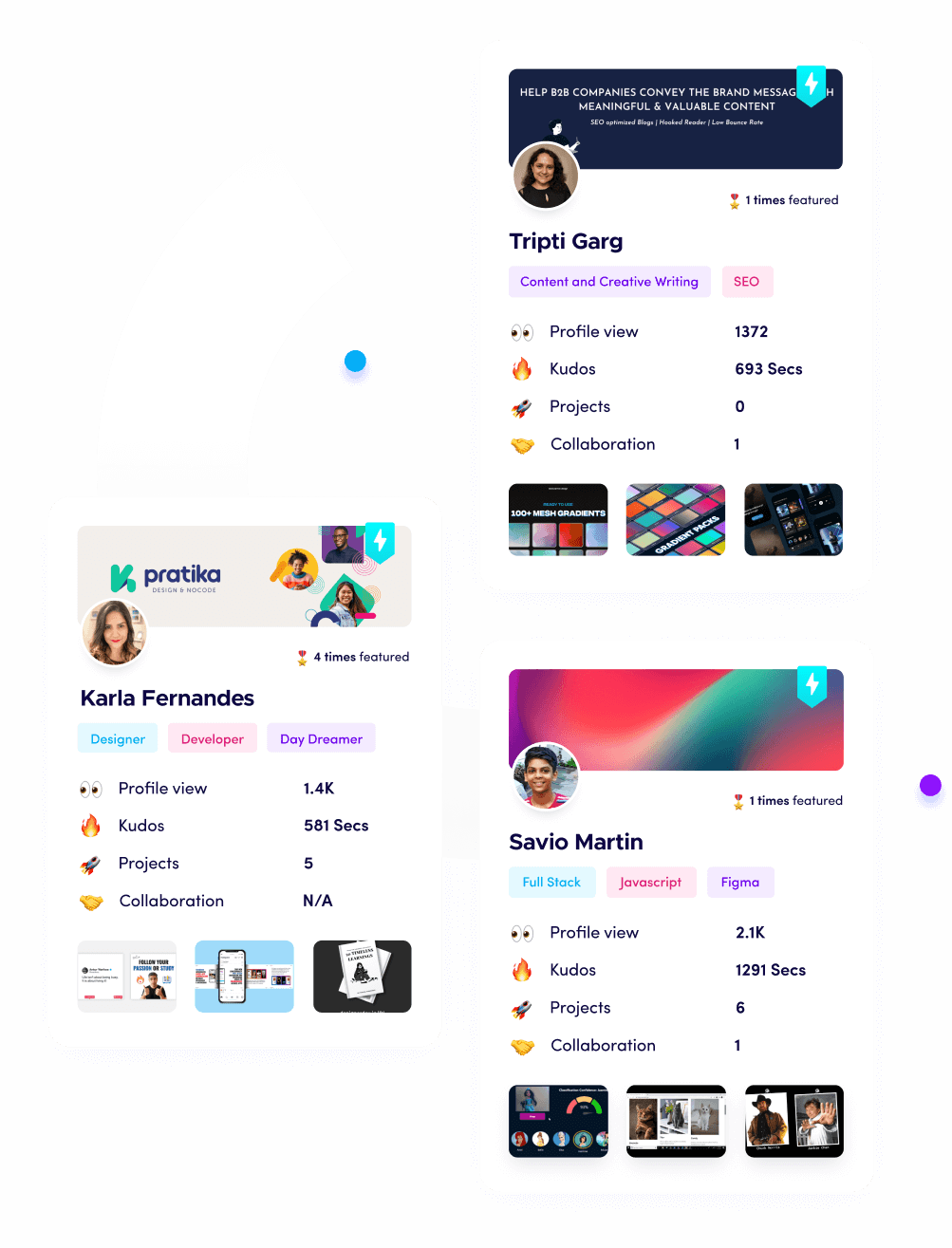

Fueler: Showcasing IoT Expertise Through Portfolios

As manufacturers adopt IoT, professionals involved in these projects need to demonstrate their skills effectively. Fueler enables engineers, data scientists, and technicians to create digital portfolios showcasing their work with IoT systems, projects, and innovations. A strong portfolio helps build credibility with employers, clients, and partners, serving as proof of expertise beyond traditional resumes.

Final Thoughts

Adopting IoT is no longer optional for European manufacturers aiming to remain competitive in a technology-driven world. By understanding key technologies, benefits, and challenges, companies can implement IoT solutions that improve efficiency, product quality, sustainability, and security. Equally important is building skills and showcasing IoT achievements effectively for long-term success.

FAQs

What are the best IoT platforms for European manufacturing in 2025?

Some leading platforms include Siemens MindSphere, Bosch IoT Suite, PTC ThingWorx, IBM Watson IoT, and Microsoft Azure IoT.

How does IoT improve manufacturing efficiency?

IoT enables real-time monitoring, predictive maintenance, automation, and energy optimization, reducing downtime and waste.

What cybersecurity measures are essential for industrial IoT?

Data encryption, multi-factor authentication, regular updates, network segmentation, and compliance with GDPR are key.

How can manufacturing companies train employees for IoT?

Providing IoT-specific training, fostering cross-team collaboration, and running pilot projects help build necessary skills.

Why is showcasing IoT work important for professionals?

Demonstrating IoT projects through portfolios builds credibility, enhances hiring prospects, and highlights practical expertise.

What is Fueler Portfolio?

Fueler is a career portfolio platform that helps companies find the best talent for their organization based on their proof of work. You can create your portfolio on Fueler, thousands of freelancers around the world use Fueler to create their professional-looking portfolios and become financially independent. Discover inspiration for your portfolio

Sign up for free on Fueler or get in touch to learn more.