Best Tech Products Defining the Next US Decade in 2026

Riten Debnath

19 Jan, 2026

The United States is entering a decade where the line between the physical and digital worlds will all but vanish. By 2026, the tech products reaching maturity aren't just "gadgets" anymore; they are the fundamental components of a new American infrastructure. We are moving away from passive tools that wait for our input toward Agentic and Physical AIsystems that can think, move, and solve problems in the real world. From the fusion of biology and technology to the rise of decentralized quantum-safe networks, these products will be the architects of American life through 2035.

I’m Riten, founder of Fueler, a skills-first portfolio platform that connects talented individuals with companies through assignments, portfolios, and projects, not just resumes/CVs. Think Dribbble/Behance for work samples + AngelList for hiring infrastructure.

1. Standard Bots RO1: The American AI Cobot

The RO1 represents a pivotal shift in US manufacturing, moving away from massive, dangerous industrial robots toward "cobots" that work safely alongside humans. Developed and assembled in Glen Cove, New York, this AI-powered robotic arm is designed to solve the labor shortage currently facing the American manufacturing and logistics sectors. Unlike legacy systems that require complex coding, the RO1 uses "no-code" spatial learning, allowing a shop foreman to teach it a new task simply by moving the arm manually or using a touchscreen. It is the first truly affordable, industrial-grade robot that small-to-medium US businesses can deploy in hours rather than weeks.

- No-Code Spatial Learning: US workers can "train" the RO1 by physically guiding the arm through a motion, which the AI then optimizes for speed and precision, eliminating the need for expensive external software engineers.

- Integrated 3D Vision Systems: The RO1 comes equipped with native AI vision that allows it to identify parts, track moving objects, and adapt to slight changes in lighting or placement without requiring a controlled environment.

- High Payload-to-Weight Ratio: Despite its compact and safe design, the RO1 can lift up to 18 kg (nearly 40 lbs), making it capable of handling heavy CNC machine tending or palletizing tasks that previously required large-scale automation.

- Human-Centric Safety Sensors: Integrated torque sensors throughout the 6-axis arm ensure that if the robot makes even slight contact with a human coworker, it stops instantly, allowing for a "cageless" factory floor.

- Rapid US-Based Deployment: Because it is manufactured in the USA, Standard Bots can ship and support these units within a 4-week window, providing American firms with a fast-acting solution to sudden production surges or labor gaps.

Pricing:

- RO1 Robotic Arm: Approximately $37,000 (Full list price).

- Leasing Options: Starts at roughly $1,500 - $2,000 per month for US businesses looking for a "Robot-as-a-Service" model.

2. Meta Orion: The Next-Gen Spatial Interface

Meta's Orion smart glasses are the product that finally makes "Spatial Computing" a mainstream reality in the United States, effectively signaling the beginning of the end for the smartphone era. These aren't just headsets; they are high-performance AR glasses that project digital overlays onto the physical world with a wide field of view. By 2026, they have become an essential tool for the US workforce, allowing architects to see digital blueprints on a physical site or medical professionals to view patient vitals in their line of sight during a procedure. The integration of "Neural Interfaces" allows users to control the system with subtle hand movements detected via a wristband, making the technology feel like a natural extension of the body.

- Holographic AR Displays: The Orion glasses use advanced waveguides to project crisp, digital information directly into the user’s field of vision, allowing for real-time navigation, data visualization, and "heads-up" communication.

- Neural Wristband Control: Utilizing EMG technology, the system detects electrical signals from the user's wrist, allowing US professionals to "click" or "scroll" using tiny, invisible finger movements without needing bulky controllers.

- Real-Time AI Environmental Context: The built-in AI "sees" what you see, allowing the glasses to identify objects, translate signs in real-time, or even provide step-by-step repair instructions for a complex piece of American machinery.

- Weight and Form Factor Optimization: Unlike previous VR/AR goggles, the Orion is designed to look and feel like standard eyewear, using lightweight magnesium frames and specialized silicon to ensure all-day comfort for the US nomadic worker.

- Seamless Ecosystem Integration: The glasses act as a primary interface for the Meta AI suite, allowing American users to dictate emails, manage smart home devices, and conduct 3D holographic meetings while on the move.

Pricing:

- Developer/Early Access Kits: Estimated around $1,500 - $2,500 (Currently targeted at the high-end professional and early-adopter market).

- Subscription Model: Some enterprise versions are offered at $50 - $100 per month including specialized software support.

3. Tesla Optimus (Gen 2): The General-Purpose Worker

The Tesla Optimus has transitioned from a prototype to a "General-Purpose Worker" that is starting to populate American gigafactories and warehouse floors. In 2026, this humanoid robot utilizes the same "Full Self-Driving" (FSD) computer and vision network found in Tesla vehicles to navigate complex, unstructured environments designed for humans. Its value lies in its versatility; it is not built for one task but can be "re-trained" via neural networks to perform anything from sorting laundry to moving heavy components. For the US economy, Optimus represents the first scalable solution for "Dull, Dirty, and Dangerous" jobs that humans are increasingly reluctant to perform.

- FSD-Powered Navigation: Optimus uses a suite of cameras and a powerful onboard AI computer to map its surroundings in real-time, avoiding obstacles and navigating busy American factory floors with high-level autonomy.

- Human-Like Dexterity: The 2026 hands feature tactile sensing and high-degree-of-freedom actuators, allowing the robot to handle delicate objects like electronic components or heavy tools with the same level of grace as a human.

- Neural Network Learning: Instead of being programmed with rigid "if-this-then-that" logic, Optimus learns by observing human demonstrations, allowing it to adapt to new tasks in any US facility without code updates.

- Battery and Power Management: Utilizing Tesla’s proprietary 4680 cell technology, the robot can operate for a full 8-hour shift on a single charge, ensuring it can keep pace with standard American work cycles.

- Mass-Production Scalability: Leveraging Tesla’s existing automotive manufacturing lines, Optimus is designed to be produced at a scale of hundreds of thousands per year, eventually making it a standard fixture in the US industrial landscape.

Pricing:

- Projected Unit Cost: Tesla targets a long-term price point of $20,000 - $30,000 (Aiming to be cheaper than a compact car).

- Early Fleet Deployment: Corporate pilot programs in the US are currently priced higher, often including maintenance and software training packages.

4. NuScale VOYGR: The Small Modular Nuclear Reactor (SMR)

As the US digital economy's energy demands skyrocket due to massive AI data centers, the NuScale VOYGR SMR has emerged as the premier "Clean Energy Product" defining the next decade. Unlike traditional, massive nuclear plants that take decades to build, VOYGR modules are factory-fabricated and shipped to the site, allowing for a much faster and more flexible rollout across the United States. These reactors provide a carbon-free, "baseload" power source that doesn't rely on the weather, making them the perfect partner for American tech hubs that need 24/7 reliability to keep their AI models running.

- Factory-Fabricated Scalability: The VOYGR modules are built in a controlled factory environment and transported via rail or truck, which significantly reduces the construction risk and cost overruns typical of traditional US nuclear projects.

- Passive Safety Architecture: The reactor is designed to shut itself down safely without human intervention or external power in the event of an emergency, meeting the most stringent US Nuclear Regulatory Commission (NRC) safety standards.

- Grid-Agnostic Deployment: Because of their smaller footprint and modular nature, these reactors can be placed directly next to large American data centers or industrial parks, reducing the strain on the national electrical grid.

- Load-Following Capabilities: Unlike older nuclear plants, VOYGR can quickly ramp power production up or down to complement intermittent renewable sources like wind and solar, creating a more resilient US energy mix.

- Long-Term Decarbonization Tool: By providing 24/7 carbon-free heat and power, SMRs are a critical product for US corporations striving to meet their "Net Zero" commitments by 2030 and beyond.

Pricing:

- Target Levelized Cost of Electricity (LCOE): Aiming for $40 - $60 per Megawatt-hour (MWh) (Competitive with natural gas and renewables in the US).

- Deployment Costs: Initial projects involve multi-billion-dollar capital investments, but modularity is expected to drop costs by 30-40% as production scales.

5. Neuralink N1: The High-Bandwidth Brain Interface

The Neuralink N1 implant has moved beyond clinical trials into a product that is beginning to redefine human capability for Americans with severe neurological conditions. In 2026, it serves as a high-bandwidth bridge between the human brain and external computers, allowing users to control digital devicesfrom smartphones to prosthetic limbswith thought alone. While its current focus is restorative, the N1 is the "defining product" of the next decade because it lays the groundwork for the eventual direct link between human intelligence and AI, a development that could fundamentally alter the American labor market and educational system.

- Ultra-Fine Thread Electrodes: The N1 uses 1,024 electrodes distributed across 64 threads that are thinner than a human hair, allowing for a high-density recording of neural activity with minimal tissue displacement.

- Robotic Surgical Implantation: The device is implanted by a specialized surgical robot that can navigate around delicate blood vessels, ensuring a high level of precision and safety for US patients.

- Wireless Power and Data: The implant is fully self-contained and charges wirelessly through the skin, allowing for 24/7 use without the need for external wires or ports protruding from the head.

- Direct Digital Control: American users can move a computer cursor, type on a virtual keyboard, or play video games using only their intentions, providing a new level of independence for those with paralysis.

- Potential for Sensory Restoration: Future iterations of the N1 system aim to use the same interface to stimulate the brain, potentially restoring sight to the blind or touch to those with spinal cord injuries.

Pricing:

- Initial Procedure Cost: Estimated between $30,000 - $40,000 (Including surgery and the device).

- Future Targets: Elon Musk has stated the goal is to bring the cost down to a level similar to LASIK eye surgery (roughly $3,000 - $5,000) over the next 10-15 years.

Final Thoughts

The products defining the next decade in the United States share a common soul: Autonomy. Whether it is a reactor that manages its own safety, a robot that learns by watching, or a brain interface that bypasses physical limitations, we are witnessing the birth of a "Self-Managing" world.

For the average American, the challenge will be staying ahead of this curve. The tools are getting smarter and more integrated into our biology and our infrastructure. The key to thriving in 2026 and beyond isn't just about owning these products; it's about mastering the orchestration of these systems. We are moving from a world of "users" to a world of "operators," and those who can leverage these high-growth products will be the ones who define the American economy for the next thirty years.

Frequently Asked Questions (FAQs)

1. Will these high-tech products actually reach rural America or stay in tech hubs?

By 2030, technologies like Small Modular Reactors (SMRs) and Agentic AI are designed specifically to decentralize the US economy. SMRs can be placed in remote locations to power local industry, while AI-powered robotics (like the RO1) allow small-town American machine shops to compete with global manufacturing giants. The goal of the next decade's tech is to bring high-end capability to wherever the worker is located.

2. How can I protect my job from being replaced by products like Optimus?

The most important shift is to move from "Performing Tasks" to "Managing Systems." An American worker who can manage a fleet of five Optimus robots is ten times more valuable than a worker doing the manual labor themselves. Focus on learning the orchestration layersthe software and logic that tell these robots what to do. Use platforms like Fueler to show that you have the "Proof of Work" in managing AI-driven workflows.

3. Are these products like Neuralink and Orion safe for long-term use?

In the US, these products must pass rigorous FDA and FCC testing before they can be sold to the public. However, 2026 is seeing a massive surge in "Neuro-Ethics" and "Spatial Privacy" legislation. While the hardware is safe (meaning it won't physically harm you), the "software safety"who owns your brain data or who can see your AR overlaysis a topic every American should stay informed about as these products go mainstream.

4. Why is the US focusing on Nuclear SMRs instead of just wind and solar?

Wind and solar are essential, but they are "intermittent." US tech giants need "Baseload Power" that runs 24/7, 365 days a year to keep AI data centers cooling and processing. Small Modular Reactors provide that constant power with a zero-carbon footprint, making them the only "product" capable of meeting the massive electricity hunger of the next generation of AI models without relying on fossil fuels.

5. Can a small US business actually afford an industrial robot like the RO1?

Yes! One of the biggest breakthroughs of 2026 is the "Robot-as-a-Service" (RaaS) model. Instead of paying $37,000 upfront, a small American business can lease a robot for $1,500 a month. This makes the "employee" cost of a robot lower than the minimum wage for a human, allowing small shops to automate their most repetitive tasks without a massive hit to their cash flow.

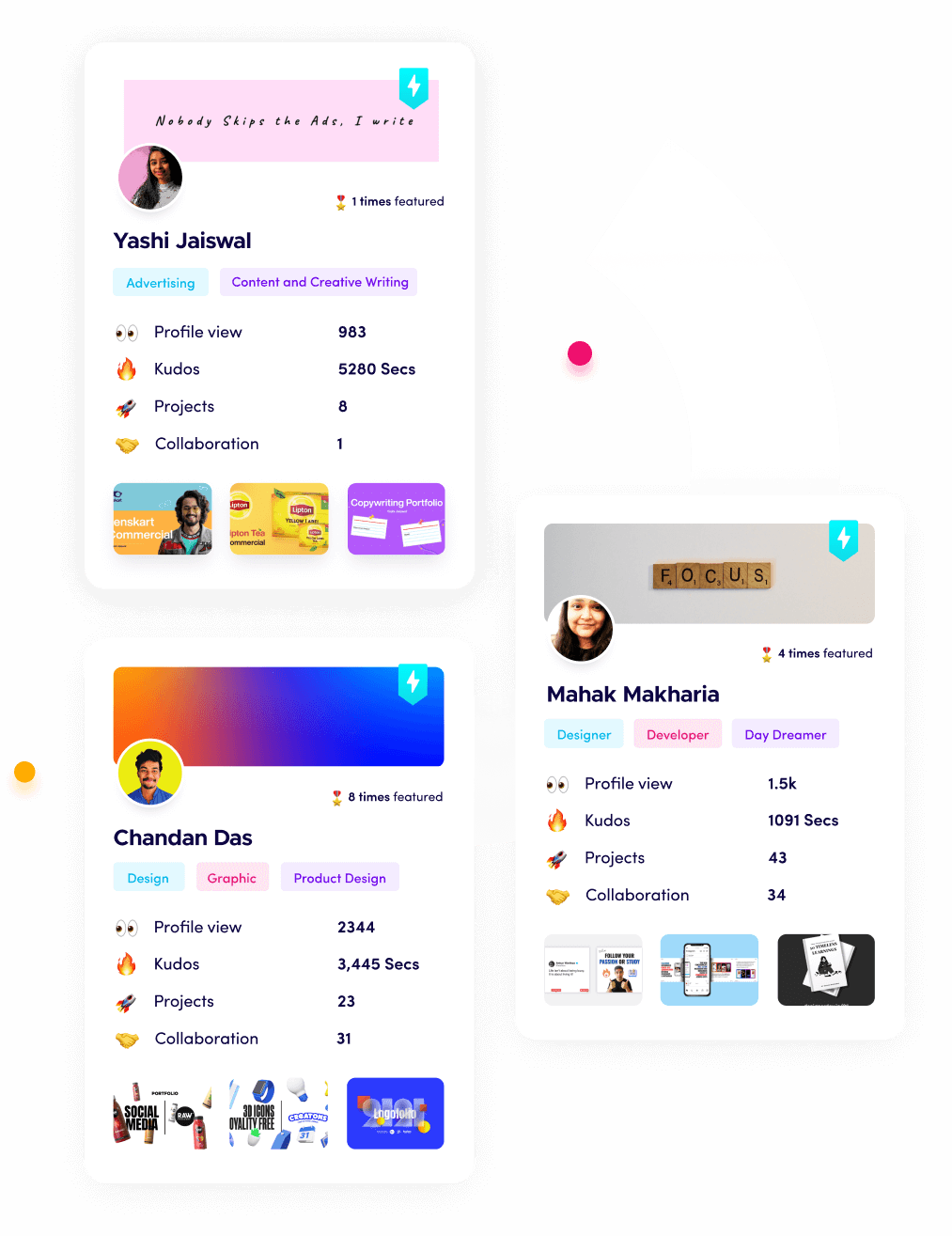

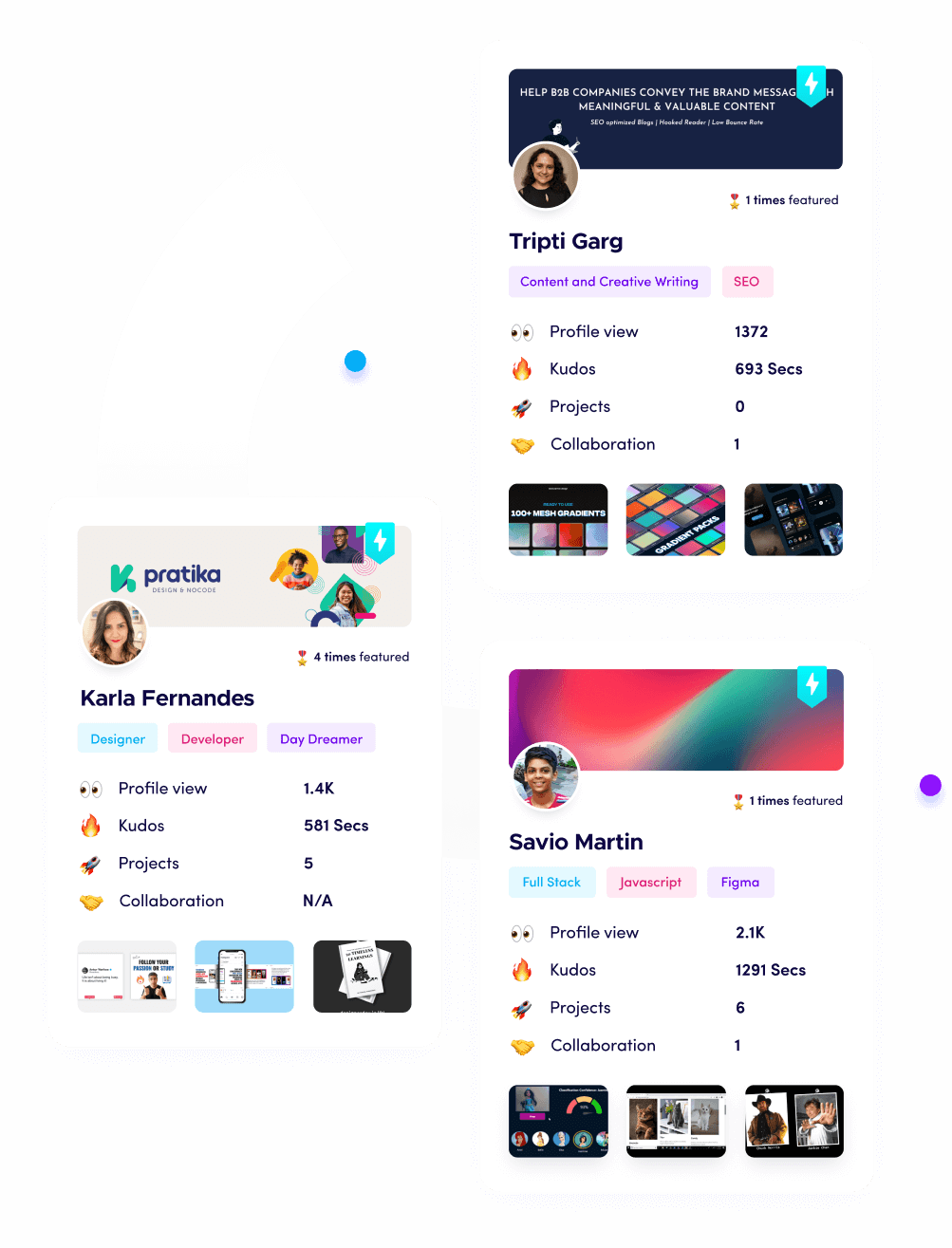

What is Fueler Portfolio?

Fueler is a career portfolio platform that helps companies find the best talent for their organization based on their proof of work. You can create your portfolio on Fueler. Thousands of freelancers around the world use Fueler to create their professional-looking portfolios and become financially independent. Discover inspiration for your portfolio

Sign up for free on Fueler or get in touch to learn more.