AI in Inventory Management: Best Practices for UK Businesses

Riten Debnath

29 Nov, 2025

In today’s fast-paced retail environment, managing inventory efficiently is vital for business success. AI-powered inventory management is transforming how UK companies forecast demand, track stock in real time, and optimize supply chains. These smart technologies help reduce waste, cut costs, and ensure customers get what they want, when they want it. In this article, explore how leveraging AI tools can revolutionize inventory management for UK businesses, making operations smarter and more responsive.

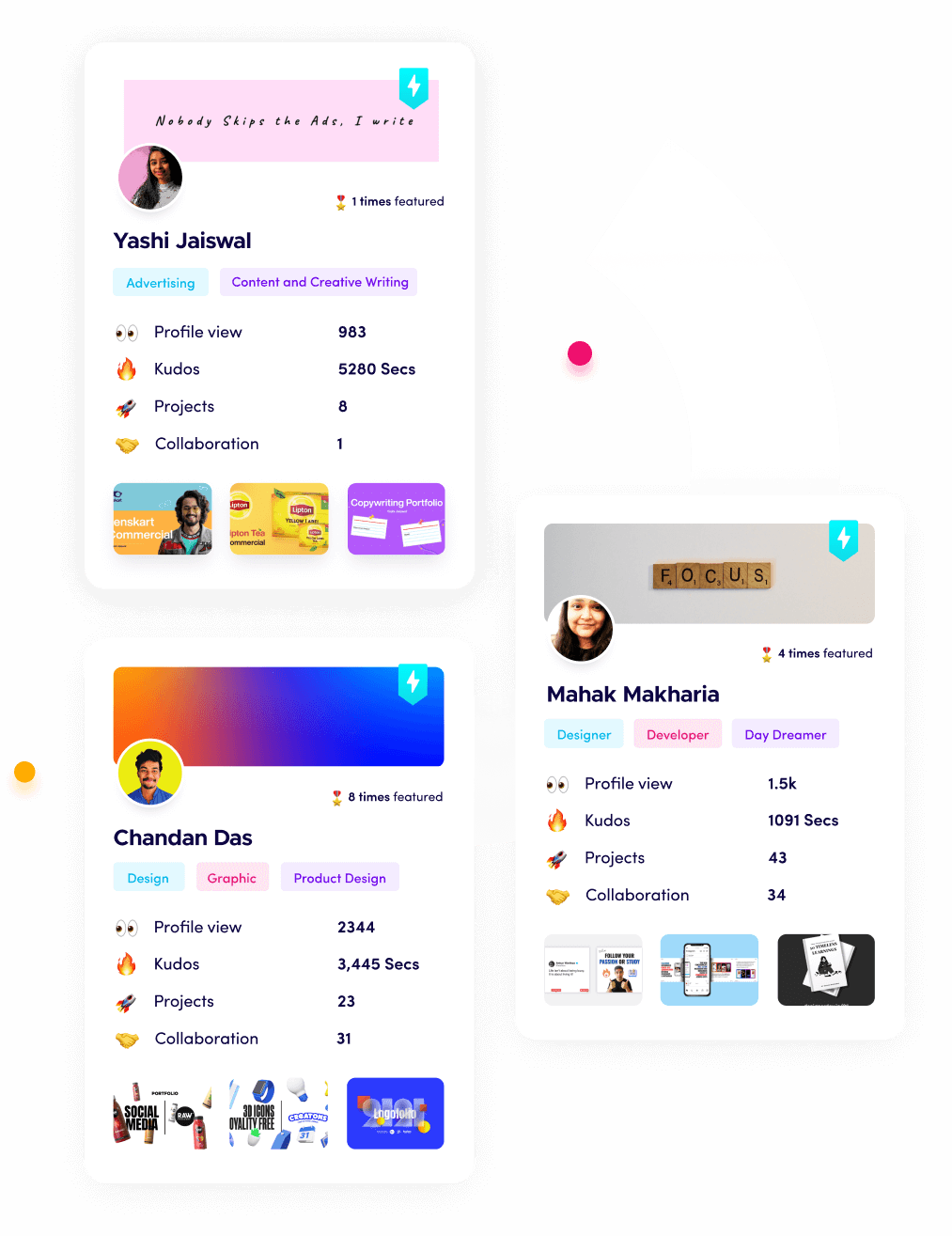

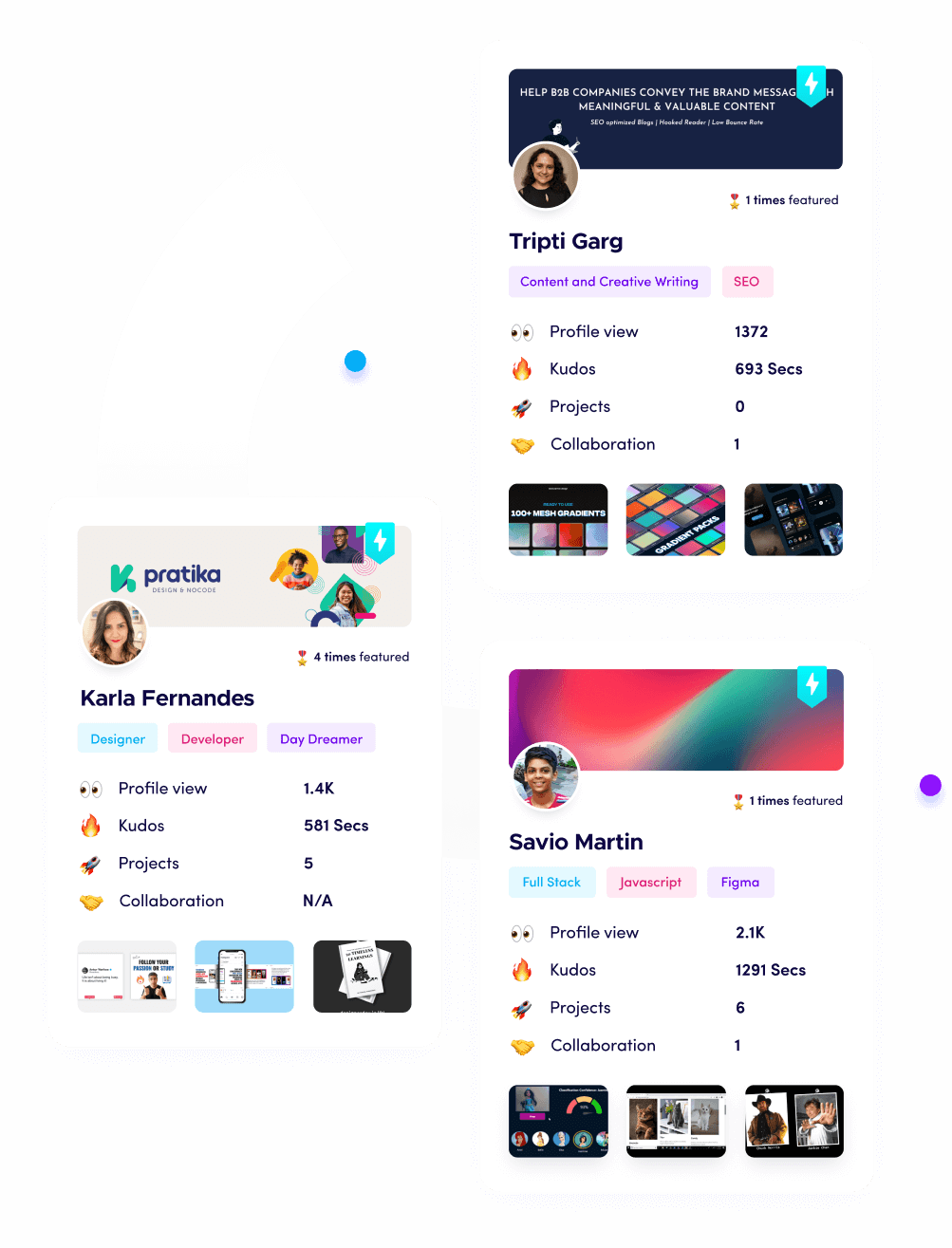

I’m Riten, founder of Fueler - a skills-first portfolio platform that connects talented individuals with companies through assignments, portfolios, and projects, not just resumes/CVs. Think Dribbble/Behance for work samples + AngelList for hiring infrastructure

Intelligent Demand Forecasting with AI

AI-powered demand forecasting uses smart algorithms to analyze sales history, market trends, weather, and economic conditions. This helps businesses predict future needs accurately, avoiding costly overstock or stockouts. Machine learning models continuously adapt to new data, reflecting changing consumer behaviour and seasons.

- AI integrates multiple sources of data, including external factors like market trends and economic conditions, to provide highly accurate demand forecasts.

- It adjusts predictions dynamically as fresh sales and environmental data arrive, helping businesses stay responsive to changes.

- Automated purchasing processes align stock replenishment with forecasted demand, reducing risks of both surplus and shortage.

- Demand forecasting supports better preparation for peak seasons, promotional events, or product launches, optimizing stock for maximum sales.

- Continuous learning improves forecasting accuracy over time, enabling smarter inventory decisions as business conditions evolve.

Why it matters: Accurate demand forecasting helps UK businesses minimize excess stock and avoid disappointed customers, ensuring smooth and profitable operations.

Real-time Inventory Tracking and Visibility

Combining AI with IoT sensors and RFID technology enables businesses to gain instant, real-time insights into stock levels across warehouses and retail locations. This visibility minimizes errors, prevents stock loss, and enables rapid responses to supply chain disruptions.

- Real-time tracking through sensors and RFID systems provides precise, continuously updated inventory data.

- Automated alerts highlight discrepancies such as misplaced stock or unexpected shortages to allow immediate corrective actions.

- Businesses can track stock movement seamlessly across multiple warehouses and retail outlets, ensuring transparency.

- Integration with order management and shipping systems creates a seamless flow of information and inventory control.

- Digital records and audit trails support compliance, simplify reporting, and enhance accountability in inventory management.

Why it matters: Real-time tracking boosts stock accuracy and responsiveness, helping businesses maintain optimal inventory levels and reduce losses from misplaced items.

Automated Reordering and Smart Replenishment

AI-driven systems calculate optimal reorder points by analyzing sales patterns, supplier lead times, and stock turnover rates. This automated replenishment reduces manual workload and ensures timely restocking of products tailored to demand fluctuations.

- AI systems autonomously calculate reorder quantities based on complex data inputs, eliminating guesswork.

- They minimize manual order placement errors by automating purchase orders aligned with inventory needs.

- Businesses can customize reorder triggers for key or seasonal products to adapt to specific operational requirements.

- Integration with supplier platforms speeds up the procurement process, improving supplier relationships and negotiation leverage.

- Alerts or automatic order placements reduce stockouts and overstocks, enhancing inventory efficiency.

Why it matters: Automated reordering helps UK businesses sustain balanced inventory, improving cash flow and minimizing costly disruptions.

AI-driven Supply Chain Optimization

Integrating AI across the supply chain improves coordination between procurement, warehousing, and logistics. Intelligent algorithms optimize routes, schedules, and supplier selection, making operations more agile and cost-effective.

- AI analyzes supply chain data in real time to identify bottlenecks or inefficiencies for timely interventions.

- Optimization of delivery routes and inventory allocation reduces transportation costs and speeds up fulfillment.

- Supplier performance metrics enable informed decisions to choose reliable partners with competitive terms.

- Predictive analytics forecast potential disruptions like delays or shortages allowing proactive management.

- Enhanced collaboration between supply chain nodes ensures better synchronization and inventory flow.

Why it matters: Optimized supply chains increase resilience and operational agility, critical for UK businesses facing dynamic market demands.

AI-powered Warehouse Automation

AI enables automation of repetitive warehouse tasks such as sorting, picking, and packaging through robotics and smart systems. This increases accuracy, productivity, and safety while freeing human workers for complex activities.

- Robotics guided by AI can handle high-volume picking and packing faster and with minimal errors.

- Automated quality checks ensure products meet standards before shipping, reducing returns and complaints.

- AI systems optimize warehouse layout based on product demand, minimizing travel time for workers and machines.

- Predictive maintenance schedules reduce equipment downtime, maintaining continuous operations.

- Integration with inventory systems enables seamless inventory updates during warehouse processes.

Why it matters: Warehouse automation powered by AI enhances productivity and accuracy, helping UK businesses meet customer expectations with faster, error-free delivery.

Predictive Analytics to Manage Slow-moving Stock

AI analyzes sales velocity and stock turnover to identify slow-moving or obsolete inventory. Businesses can then take proactive steps such as promotions or stock adjustments to optimize inventory turnover.

- Machine learning models flag products with decreasing demand, enabling timely intervention.

- Insights on slow movers help businesses avoid tying up capital in stagnant inventory.

- AI suggests targeted discounts or bundling strategies to accelerate clearance of aging stock.

- Accurate forecasting improves purchasing decisions, reducing the risk of future excess stock.

- Inventory space is freed up for faster-moving, higher-demand products, improving cash flow.

Why it matters: Managing slow-moving stock efficiently improves profitability and inventory health for UK businesses, avoiding unnecessary costs.

Cloud-based AI Inventory Platforms

Cloud technology enables scalable AI inventory solutions accessible to businesses of all sizes. Cloud platforms offer flexibility, easy updates, and integrations with other business tools without heavy upfront costs.

- Businesses can access advanced AI features anytime from anywhere via cloud platforms.

- Scalable infrastructure supports growth without expensive hardware investments.

- Regular automatic software updates keep AI models current with the latest algorithms.

- Integration with ERP, CRM, and other systems streamlines operations and data sharing.

- Cloud security protocols protect sensitive inventory and business data.

Why it matters: Cloud-based AI platforms democratize access to powerful inventory management technologies, allowing UK businesses to scale efficiently and innovate rapidly.

Fueler: Showcase Your Skills with Work Samples

Navigating today’s tech-driven business landscape requires more than just resumes; it's about demonstrating skills through real projects and assignments. Fueler provides a portfolio platform for professionals to showcase their expertise effectively. Whether you specialize in inventory management, AI integration, or supply chain technology, Fueler helps you get noticed by hiring companies with authentic work samples and project outcomes.

Final Thoughts

AI is revolutionizing inventory management for UK businesses by automating routine tasks, enhancing demand forecasting, and optimizing supply chains. Leveraging AI-powered tools leads to higher stock accuracy, reduced costs, and improved customer satisfaction. Embracing these technologies enables companies to stay competitive, agile, and prepared for future growth challenges.

FAQs

What are the best AI tools for inventory management in the UK?

Leading AI inventory tools include EazyStock, Unleashed, and platforms with integrated IoT and machine learning for forecasting and real-time tracking.

How does AI improve demand forecasting accuracy?

AI uses complex algorithms analyzing historical data and market trends, adapting forecasts dynamically as new data arrives, reducing overstock and stockouts.

Can small businesses in the UK benefit from AI inventory management?

Yes, cloud-based scalable AI platforms allow small and medium businesses to leverage advanced inventory optimization without heavy upfront investment.

What role does IoT play in AI inventory management?

IoT sensors and RFID devices collect real-time data on stock levels and location, enabling AI to provide precise visibility and proactive issue alerts.

How does AI optimize warehouse operations?

AI powers robotic automation, dynamic warehouse layout optimization, and predictive maintenance, improving efficiency, accuracy, and safety.